We are one of the biggest ASTM A213 TP316ti Tube supplier in India

The austenitic Stainless Steel 316ti Tube is comprised of molybdenum-bearing stainless steel. This is the titanium-stabilized version of the material, and the alloy is more resistant to general corrosion. It is also more resistant to crevice corrosion and pitting than typical austenitic 304 SS. The features of 316h tubing solutions include high creep and stress-rupture resistance. At increased temperatures, the material also exhibits improved tensile strength. The ASTM A213 TP316ti Tube supplier provides high-quality titanium-stabilized tubes with a stabilised structure that provides good resistance to chromium carbide precipitation, which is the primary source of sensitization. This is why the Stainless Steel 316ti Seamless Tube may be used at high temperatures for an extended period of time without compromising its corrosion resistance.

Stainless Steel 316ti Seamless Tube and ASTM A213 TP316ti Tubing can be joined by conventional welding, brazing and soldering processes.

The material used to make the DIN 1.4571 Coiled Tubing is a higher carbon version of the 316 grade stainless steel. Its chemical composition includes chromium and nickel, which give it its qualities. The majority of UNS S31635 Condenser Tubes are dimensionally accurate and can be utilized efficiently in high-temperature environments. The tubes are quite robust due to the high carbon concentration of the material. The ASTM A213 TP316ti Exhaust Tubing can be customised in terms of shape, size, dimension, and finish to meet individual needs. Because of these qualities, these tubes are frequently employed in a variety of applications such as chemical and marine. Because they are food safe, these tubes are also commonly used.

Table of content

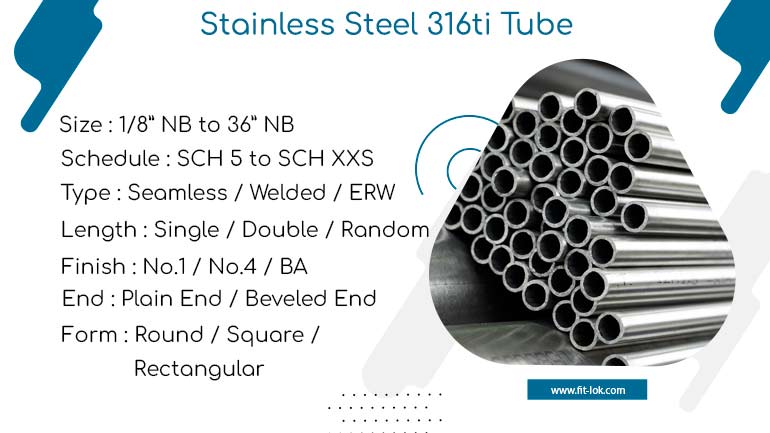

- Specification of Stainless steel 316ti tube

- SS 316ti Tube sizes

- ASTM A213 TP316Ti Tubing Chemical composition

- UNS S31635 ERW Tube Mechanical properties

- SS 316ti round tube Equivalent grade

- Allowable Temperature of DIN 1.4571 boiler tube

- Stainless Steel 316TI Seamless Tube Types

- ASME SA213 TP316Ti Tube stock list

- ASTM A213 TP316Ti Welded Tube Dimensions

- SS 316Ti Cold Rolled Coiled Tubing Tolerances

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316TI | min. | – | – | – | – | – | 16.0 | 2.0-3.0 | 10.0 | – |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | 0.1 | ||

Annealing of DIN 1.4571 Coiled Tubing and UNS S31635 Condenser Tubes improves its resistance to corrosion and oxidation.

| Grade | Tensile Strength (MPa) Minimum | Yield Strength (MPa) Minimum | Elongation (% in 50mm) Minimum | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316TI | 515 | 205 | 35 | 75 | 205 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316TI | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

We can provide 316ti Stainless Steel Rectangular Tubing and ASTM A213 TP316ti Exhaust Tubing in basically any size

Suitable to use up to 1600 – 1650°F (870-900°C)

ASTM A213 TP316ti welded Tube

SS 316ti Heat exchanger Tube

Stainless Steel 316ti Seamless Tube

ASTM A213 TP316ti Tubing

DIN 1.4571 Coiled Tubing

UNS S31635 Condenser Tubes

| ASME SA312 TP 316Ti Seamless Steel Pipe | 316Ti SS Cold Drawn Welded Pipes |

| SS A312 TP316Ti Welded Pipe | UNS S31635 Cold Drawn Pipes |

| ASTM A312 TP 316Ti ERW Pipe | Schedule 5S Stainless Steel 1.4571 Seamless Pipes |

| UNS S31635 EFW Pipe | Schedule 40 316Ti Stainless Steel Pipe |

| Stainless Steel 1.4571 Cold Drawn Seamless Pipes | ASTM A312 TP 316Ti Precision Pipe |

| Stainless Steel 316Ti Seamless Steel Precision Pipe | High pressure ASME SA312 TP 316Ti Pipe |

| 316Ti Stainless Steel Cold Drawn Seamless Pipes | Stainless Steel 1.4571 Electropolished Pipe |

| ASTM A312 TP 316Ti Custom Pipe | Stainless Steel 316Ti Cold Drawn Pipes |

| 316Ti SS Round Pipe | UNS S31635 Exhaust Pipe |

The thickness of SA 213 Gr 316ti Straight Tubing and SS 316ti Heat exchanger Tube covers a range starting from Schedule 5 and ending at Schedule XXS.

| OD inches | Ave. Wall inches | D/t Ratio | ID inches | Tube Cross Sectional Area (in2) | Internal Area (in2) |

|---|---|---|---|---|---|

| 0.250 | 0.020 | 12.50 | 0.210 | 0.0145 | 0.0346 |

| 0.250 | 0.028 | 8.93 | 0.194 | 0.0195 | 0.0296 |

| 0.250 | 0.035 | 7.14 | 0.180 | 0.0236 | 0.0254 |

| 0.250 | 0.049 | 5.10 | 0.152 | 0.0309 | 0.0181 |

| 0.250 | 0.065 | 3.85 | 0.120 | 0.0378 | 0.0113 |

| 0.375 | 0.020 | 18.75 | 0.335 | 0.0223 | 0.0881 |

| 0.375 | 0.028 | 13.39 | 0.319 | 0.0305 | 0.0799 |

| 0.375 | 0.035 | 10.71 | 0.305 | 0.0374 | 0.0731 |

| 0.375 | 0.049 | 7.65 | 0.277 | 0.0502 | 0.0603 |

| 0.375 | 0.065 | 5.77 | 0.245 | 0.0633 | 0.0471 |

| 0.500 | 0.020 | 25.00 | 0.460 | 0.0302 | 0.1662 |

| 0.500 | 0.028 | 17.86 | 0.444 | 0.0415 | 0.1548 |

| 0.500 | 0.035 | 14.29 | 0.430 | 0.0511 | 0.1452 |

| 0.500 | 0.049 | 10.20 | 0.402 | 0.0694 | 0.1213 |

| 0.500 | 0.065 | 7.69 | 0.370 | 0.0888 | 0.1075 |

| 0.500 | 0.083 | 6.02 | 0.334 | 0.1087 | 0.0876 |

| 0.625 | 0.020 | 31.25 | 0.585 | 0.0380 | 0.2688 |

| 0.625 | 0.028 | 22.32 | 0.569 | 0.0525 | 0.2543 |

| 0.625 | 0.035 | 17.86 | 0.555 | 0.0649 | 0.2419 |

| 0.625 | 0.049 | 12.76 | 0.527 | 0.0887 | 0.2181 |

| 0.625 | 0.065 | 9.62 | 0.495 | 0.1144 | 0.1924 |

| 0.625 | 0.083 | 7.53 | 0.459 | 0.1413 | 0.1655 |

| 0.625 | 0.095 | 6.58 | 0.435 | 0.1582 | 0.1486 |

| 0.625 | 0.109 | 5.73 | 0.407 | 0.1767 | 0.1301 |

| 0.750 | 0.028 | 26.79 | 0.694 | 0.0635 | 0.3783 |

| 0.750 | 0.035 | 21.43 | 0.680 | 0.0786 | 0.3632 |

| 0.750 | 0.049 | 15.31 | 0.652 | 0.1079 | 0.3339 |

| 0.750 | 0.065 | 11.54 | 0.620 | 0.1399 | 0.3019 |

| 0.750 | 0.083 | 9.04 | 0.584 | 0.1739 | 0.2679 |

| 0.750 | 0.095 | 7.89 | 0.560 | 0.1955 | 0.2463 |

| 0.750 | 0.109 | 6.88 | 0.532 | 0.2195 | 0.2223 |

| 0.750 | 0.120 | 6.25 | 0.510 | 0.2375 | 0.2043 |

| 0.875 | 0.020 | 43.75 | 0.835 | 0.0537 | 0.5476 |

| 0.875 | 0.028 | 31.25 | 0.819 | 0.0745 | 0.5268 |

| 0.875 | 0.035 | 25.00 | 0.805 | 0.0924 | 0.5090 |

| 0.875 | 0.049 | 17.86 | 0.777 | 0.1272 | 0.4742 |

| 0.875 | 0.065 | 13.46 | 0.745 | 0.1654 | 0.4359 |

| 0.875 | 0.083 | 10.54 | 0.709 | 0.2065 | 0.3948 |

| 0.875 | 0.095 | 9.21 | 0.685 | 0.2328 | 0.3685 |

| 0.875 | 0.109 | 8.03 | 0.657 | 0.2623 | 0.3390 |

| 0.875 | 0.120 | 7.29 | 0.635 | 0.2846 | 0.316L7 |

| 1.000 | 0.028 | 35.71 | 0.944 | 0.0855 | 0.6999 |

| 1.000 | 0.035 | 28.57 | 0.930 | 0.1061 | 0.6793 |

| 1.000 | 0.049 | 20.41 | 0.902 | 0.1464 | 0.6390 |

| 1.000 | 0.065 | 15.38 | 0.870 | 0.1909 | 0.5945 |

| 1.000 | 0.083 | 12.05 | 0.834 | 0.2391 | 0.5463 |

| 1.000 | 0.095 | 10.53 | 0.810 | 0.2701 | 0.5153 |

| 1.000 | 0.109 | 9.17 | 0.782 | 0.3051 | 0.4803 |

| 1.000 | 0.120 | 8.33 | 0.760 | 0.3318 | 0.4536 |

| 1.000 | 0.134 | 7.46 | 0.732 | 0.3646 | 0.4208 |

| 1.250 | 0.035 | 35.71 | 1.180 | 0.1336 | 1.0936 |

| 1.250 | 0.049 | 25.51 | 1.152 | 0.1849 | 1.0423 |

| 1.250 | 0.065 | 19.23 | 1.120 | 0.2420 | 0.9852 |

| 1.250 | 0.083 | 15.06 | 1.084 | 0.316L3 | 0.9229 |

| 1.250 | 0.095 | 13.16 | 1.060 | 0.3447 | 0.8825 |

| 1.250 | 0.109 | 11.47 | 1.032 | 0.3907 | 0.8365 |

| 1.250 | 0.120 | 10.42 | 1.010 | 0.4260 | 0.8012 |

| 1.250 | 0.134 | 9.33 | 0.982 | 0.4698 | 0.7574 |

| 1.500 | 0.035 | 42.86 | 1.430 | 0.1611 | 1.6061 |

| 1.500 | 0.049 | 30.61 | 1.402 | 0.2234 | 1.5438 |

| 1.500 | 0.065 | 23.08 | 1.370 | 0.2930 | 1.4741 |

| 1.500 | 0.083 | 18.07 | 1.334 | 0.3695 | 1.3977 |

| 1.500 | 0.095 | 15.79 | 1.310 | 0.4193 | 1.3478 |

| 1.500 | 0.109 | 13.76 | 1.282 | 0.4763 | 1.2908 |

| 1.500 | 0.120 | 12.50 | 1.260 | 0.5202 | 1.2469 |

| 1.500 | 0.134 | 11.19 | 1.232 | 0.5750 | 1.1921 |

| 1.500 | 0.148 | 10.14 | 1.204 | 0.6286 | 1.1385 |

| 1.750 | 0.035 | 50.00 | 1.680 | 0.1886 | 2.2167 |

| 1.750 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 1.750 | 0.065 | 26.92 | 1.620 | 0.3441 | 2.0612 |

| 1.750 | 0.083 | 21.08 | 1.584 | 0.4347 | 1.9706 |

| 1.750 | 0.095 | 18.42 | 1.560 | 0.4939 | 1.9113 |

| 1.750 | 0.109 | 16.06 | 1.532 | 0.5619 | 1.8433 |

| 1.750 | 0.120 | 14.58 | 1.510 | 0.6145 | 1.7908 |

| 1.750 | 0.134 | 13.06 | 1.482 | 0.6803 | 1.7250 |

| 1.750 | 0.148 | 11.82 | 1.454 | 0.7449 | 1.6604 |

| 1.750 | 0.165 | 10.61 | 1.420 | 0.8216 | 1.5837 |

| 2.000 | 0.035 | 57.14 | 1.930 | 0.2161 | 2.9255 |

| 2.000 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 2.000 | 0.065 | 30.77 | 1.870 | 0.3951 | 2.7465 |

| 2.000 | 0.083 | 24.10 | 1.834 | 0.4999 | 2.6417 |

| 2.000 | 0.095 | 21.05 | 1.810 | 0.5685 | 2.5730 |

| 2.000 | 0.109 | 18.35 | 1.782 | 0.6475 | 2.4941 |

| 2.000 | 0.120 | 16.67 | 1.760 | 0.7087 | 2.4328 |

| 2.000 | 0.134 | 14.93 | 1.732 | 0.7855 | 2.3561 |

| 2.000 | 0.148 | 13.51 | 1.704 | 0.8611 | 2.2805 |

| 2.000 | 0.165 | 12.12 | 1.670 | 0.9512 | 2.1904 |

| Specification | Size OD Range Inches | Tolerances | |||

|---|---|---|---|---|---|

| O.D. | Wall | ||||

| Plus | Minus | Plus | Minus | ||

| ASTM-A-632 | Under 0.094 | .002″ | .000″ | 10% | 10% |

| Welded & Seamless | .094 to 0.187 | .003″ | .000″ | 10% | 10% |

| Cold Finished | .188 to 0.500 | .004″ | .000″ | 10% | 10% |

| ASTM-A-269 | Under 0.500 | .005″ | .005″ | 15% | 15% |

| Welded & Seamless | 0.500 to 1.499 | .005″(1) | 005″ | 10% | 10% |

| General Service | 1.500 to 3.499 | .010″(2) | .010″ | 10% | 10% |

| Cold Finished | 3.500 to 5.499 | .015″(3) | .015″ | 10% | 10% |

| Hot Finished | 5.500 to 8.000 | .030″ | .030″ | 10% | 10% |

Application of ASTM A213 TP316ti Tubing

- Brewing equipment

- Marine applications

- Aerospace industry

- Dairy equipment

- Automotive manufacturing

Packaging of DIN 1.4571 Coiled Tubing

Safeguard delicate items with plastic or paper sleeves when bundling them for shipment. Wooden crates are sturdy and reliable packaging solutions for transporting goods securely. Cardboard boxes are versatile and eco-friendly options for organizing your items during transit.

Frequently asked questions

Can AISI 316ti Square Tubing be used in oxidizing environments?

Yes, AISI 316ti Square Tubing are highly resistant to oxidation, making them suitable for applications involving exposure to air and high temperatures.

Are 316ti Stainless Steel Square Tubing resistant to sulfidation?

316ti Stainless Steel Square Tubing exhibit good resistance to sulfidation, making them suitable for applications in sulfur-containing environments.

What are the common applications of ASTM A213 TP316ti welded Tube?

Common applications of ASTM A213 TP316ti welded Tube include furnace components, heat exchangers, radiant tubes, and high-temperature piping in various industries such as petrochemical, power generation, and heat treatment.

Can SS 316ti Heat exchanger Tube withstand thermal cycling?

Yes, SS 316ti Heat exchanger Tube are designed to withstand thermal cycling, which is crucial in applications involving rapid heating and cooling.

Are Stainless Steel 316ti Seamless Tube compatible with furnace and heat exchanger applications?

Yes, Stainless Steel 316ti Seamless Tube are commonly used in furnace and heat exchanger applications due to their high-temperature strength and excellent resistance to thermal cycling.