Top notch ASTM A213 TP347 Tube supplier in India

In the aerospace industry, 347 Stainless Steel Tube is widely utilised. The ASTM A213 TP347 material is an austenitic stainless steel with exceptional intergranular corrosion resistance. It occurs primarily when the tubes are subjected to temperatures in the carbide precipitation range of 427 to 816 degrees Celsius. It offers corrosion resistance qualities comparable to 304/304L stainless steel. In its alloy, the SA213 TP347 material contains components like as niobium. This explains why it has good mechanical qualities at high temperatures. In annealed conditions, the material is nonmagnetic and can only be toughened by cold working.

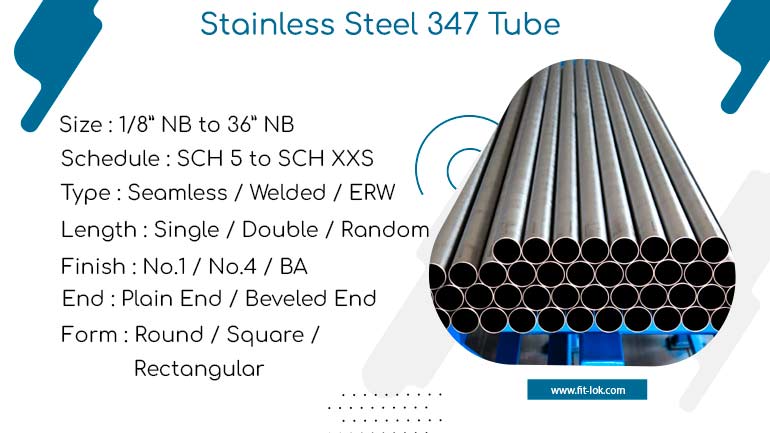

Count on our expertise and industry knowledge as the leading stockist and distributor of high-temperature Stainless Steel Type 347 ERW Tubing and SS Grade 347 Round Tubing.

Cold-drawn SS 347 Seamless Tube has uniform tolerances and improved machinability. When compared to hot-rolled goods, it has greater strength and tolerances. The seamless tubes are tougher and more leak-proof than the 347 SS Welded Tubing alternatives. It’s because the pipes have no weak seams. The oil and gas industries generally use seamless AISI 347 Heat Exchanger Tubes. They can be found mostly in control lines, subsea safety valves, and chemical injection. Cold-drawn seamless tubes can also be found in the chemical processing and instrumentation industries, where tight dimensional tolerances are required.

WNR 1.4550 Condenser & Heater Tubes’ key advantage is their resistance to intergranular corrosion. It is developed for increased creep resistance and strong strength at temperatures above 537 degrees Celsius. It also has better rupture properties than 304 ss. UNS S34700 Bright Annealed Tubes are suited for a variety of high temperature applications. As a result, they can be found in heater and condenser tubes, boilers, pressure vessels, and other places. It has outstanding mechanical qualities and, as a result of stabilisation, it is more corrosion resistant than 304 ss.

Table of content

- 347 stainless steel tube Specification

- Size Chart of Alloy 347 Round Tubing

- Various types of 347 SS tube

- ASTM A213 TP 347 Seamless Tube Chemical composition

- UNS S34700 Welded Tubing Mechanical properties

- AISI 347 welded tube Physical properties

- SA213 TP347 Polished Tube Equivalent grade

- ASTM A213 TP347 Tube Tolerance chart

- Ready stock of stainless steel 347 tube

- Testing requirements of AISI 347 welded tube

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

AISI 347 welded tube

347 Stainless Steel Tubing

Stainless Steel Type 347 ERW Tubing

SS Grade 347 Round Tubing

SA213 TP347 Polished Tube

ASTM A213 TP347 Exhaust Tubing

SA213 TP347 Polished Tube and SA213 Tp347 Cres Tubing has moderate strength with excellent cold formability, weld ability.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 347 | min. | – | – | – | – | – | 17.0 | – | 9.0 | – |

| max. | 0.08 | 2.0 | 1.0 | 0.040 | 0.030 | 20.0 | 13.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 347 | 515 | 205 | 40 | 92 | 201 |

When considering UNS S34700 Condenser Tubes and 347 Stainless Steel Rectangular Tubing one must take into account the thickness range from Schedule 5 to Schedule XXS.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 347 | 8000 | 193 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 740 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

| Specification | Size OD Range Inches | Tolerances | |||

|---|---|---|---|---|---|

| O.D. | Wall | ||||

| Plus | Minus | Plus | Minus | ||

| ASTM-A-632 | Under 0.094 | .002″ | .000″ | 10% | 10% |

| Welded & Seamless | .094 to 0.187 | .003″ | .000″ | 10% | 10% |

| Cold Finished | .188 to 0.500 | .004″ | .000″ | 10% | 10% |

| ASTM-A-269 | Under 0.500 | .005″ | .005″ | 15% | 15% |

| Welded & Seamless | 0.500 to 1.499 | .005″(1) | 005″ | 10% | 10% |

| General Service | 1.500 to 3.499 | .010″(2) | .010″ | 10% | 10% |

| Cold Finished | 3.500 to 5.499 | .015″(3) | .015″ | 10% | 10% |

| Hot Finished | 5.500 to 8.000 | .030″ | .030″ | 10% | 10% |

Choose cold drawn ASTM A213 TP347 Exhaust Tubing and DIN 1.4550 Tubing for superior surface finish and tight tolerances.

| ASME SA213 TP347 Square Tubing | Stainless Steel Type 347 EFW Tube |

| SA213 347 SS Decorative Tube | ASME SA213 TP347 Polished Tube |

| DIN 1.4550 Stainless Steel 347 Polish Tube | ASTM A 213 347 Stainless Steel Elliptical and Oval Tubes |

| ASTM A 213 347 Stainless Steel Seamless Tubing | SS 347 Coil Tubing |

| SA 213 TP 347 Stainless Steel High Pressure Tube | ASTM A213 TP 347 Heat exchanger Tubes |

| 347 Stainless Steel Exhaust Tubing | Stainless Steel DIN 1.4550 ERW Tube |

| SA213 TP347 Rectangular Tubing | SS UNS S34700 ERW Tubing |

| JIS SUS347 UNS S34700 Cold Drawn Tube | SA 213 Grade 347 Condenser Tubes |

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Application of SS Grade 347 Round Tubing

- Marine applications

- Brewing equipment

- Automotive manufacturing

- Aerospace industry

- Dairy equipment

Packaging of ASTM A213 TP347 Tube

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

Are AISI 347 welded tube resistant to carburization and nitriding?

Yes, AISI 347 welded tube are highly resistant to carburization and nitriding, making them suitable for applications involving carbon-rich or nitrogen-rich environments.

What are the available sizes and dimensions of 347 Stainless Steel Tubing?

347 Stainless Steel Tubing are available in various sizes and dimensions, ranging from small diameters to larger sizes, depending on the manufacturer and specific requirements.

Can Stainless Steel Type 347 ERW Tubing be used in the petrochemical industry?

Yes, Stainless Steel Type 347 ERW Tubing are commonly used in the petrochemical industry for applications such as furnace tubes, reformer tubes, and heat exchangers due to their high-temperature strength and corrosion resistance.

Do SS Grade 347 Round Tubing exhibit good creep resistance?

SS Grade 347 Round Tubing exhibit excellent creep resistance, making them suitable for applications that involve prolonged exposure to high temperatures.

Are SA213 TP347 Polished Tube commonly used in power generation plants?

Yes, SA213 TP347 Polished Tube are widely used in power generation plants, particularly in boilers, superheaters, and reheaters, where they withstand high-temperature and corrosive conditions.