We are 20 years old ASTM A213 TP904l Tube supplier in India

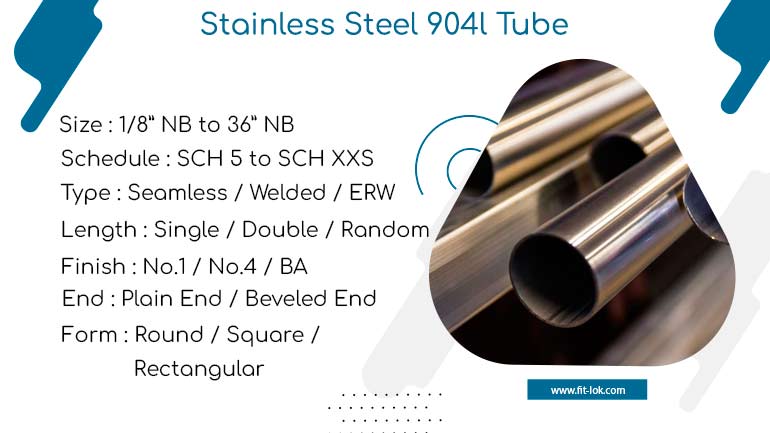

The Stainless Steel 904l Tube is manufactured of stainless steel 904L grade, which is a non-stabilized austenitic grade with low carbon concentrations. They contain a high molybdenum and nickel concentration in their chemical composition, as well as traces of copper, which strengthens the resistance of ASTM A213 TP904l Tube against corrosion and reducing acids. They are also resistant to carburization and cracking. They come in a variety of sizes with adjustable diameters. They are also available in a variety of schedules that are suitable for a variety of purposes. Several testing is performed by manufacturers to guarantee that the SS Grade 904l Round Tubing meets various national and international requirements. These tubes are employed in a variety of industries, including petrochemical, aerospace, and medicinal.

Reliable supplier offering cost-effective SS Grade 904l Round Tubing and SB 677 904L Welded Tube in India

Because of the low carbon percentage, the SB 677 904L Welded Tube is quite simple to manufacture. They have higher strength and can withstand corrosion better than standard welded tube grades. They have a minimum tensile strength of 490 MPa and a minimum yield strength of 220 MPa. They have 36% elongation and are also fairly hard. One of the best aspects of 904L Tubing solutions is their increased durability and low maintenance requirements. These tubes come in a variety of forms and sizes, and each is employed for a specific purpose. Square tubes, for example, are more useful in structural applications.

The SB677 Tp904l Annealed Tube is available in a variety of schedules, and the capacity of the tube to withstand pressure varies according to the schedule. These WNR 1.4539 Heat Exchanger Tubing can withstand temperatures of up to 60 degrees Celsius. The chemical makeup of the 904L Stainless Steel Seamless tube material includes 25% nickel and 4.5% molybdenum, which improves its resistance to chloride-related stress corrosion, cracking, and pitting. The inclusion of molybdenum improves the material’s overall characteristics. The Alloy 904L Condenser tubes are nonmagnetic under all situations and have excellent formability and weldability. Even at cryogenic temperatures, the grade exhibits excellent toughness.

Table of content

- 904L Stainless Steel Tubing Specification

- Sizes of ASTM B677 UNS N08904 Tube

- 904L SS tube types

- SA 213 TP 904L ERW Tubing Chemical composition

- Stainless steel 904L Welded Tube Mechanical properties

- AISI 904l Tube Physical properties

- WNR 1.4539 Heat Exchanger Tubing Equivalent grade

- 904L SS Seamless Tube Tolerance chart

- Schedule chart of ASME SA 213 TP 904L tube

- Stock list of Stainess steel 904l tube

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

SS 904L ERW Tubes

SS Grade 904l Round Tubing

ASTM B677 UNS N08904 Tube

Alloy 904L Condenser tubes

ASTM B677 TP904l Exhaust Tubing

DIN 1.4539 Cold Drawn Tubing

SB677 Tp904l Annealed Tube and WNR 1.4539 Heat Exchanger Tubing is completely resistant to corrosion at high temperature environment.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

The thickness of Alloy 904L Condenser tubes and ASTM B677 TP904l Exhaust Tubing can be categorized within the range of Schedule 5 to Schedule XXS.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 904L | 8000 | 200 | 15.0 | – | – | 13.0 | – | 500 | 850 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

| Specification | Size OD Range Inches | Tolerances | |||

|---|---|---|---|---|---|

| O.D. | Wall | ||||

| Plus | Minus | Plus | Minus | ||

| ASTM-A-632 | Under 0.094 | .002″ | .000″ | 10% | 10% |

| Welded & Seamless | .094 to 0.187 | .003″ | .000″ | 10% | 10% |

| Cold Finished | .188 to 0.500 | .004″ | .000″ | 10% | 10% |

| ASTM-A-269 | Under 0.500 | .005″ | .005″ | 15% | 15% |

| Welded & Seamless | 0.500 to 1.499 | .005″(1) | 005″ | 10% | 10% |

| General Service | 1.500 to 3.499 | .010″(2) | .010″ | 10% | 10% |

| Cold Finished | 3.500 to 5.499 | .015″(3) | .015″ | 10% | 10% |

| Hot Finished | 5.500 to 8.000 | .030″ | .030″ | 10% | 10% |

Hot rolled DIN 1.4539 Cold Drawn Tubing and SS 904L ERW Tubes is ideal for applications requiring high strength and toughness.

| Nominal Pipe Size | Outside Diameter | Schedule 5 S | Schedule 10 S | Schedule 20 S | Schedule 40 S | Schedule 80 S | Schedule 160 S | XXS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) | WT mm | WEIGHT (KGM) |

| 3 | 1/8 | 10.3 | 1.2 | 0.20 | 1.24 | 0.28 | 1.5 | 0.33 | 1.73 | 0.37 | 2.41 | 0.47 | – | – | – | – |

| 6 | 1/4 | 13.7 | 1.2 | 0.37 | 1.65 | 0.49 | 2.00 | 0.58 | 2.24 | 0.630 | 3.02 | 0.80 | – | – | – | – |

| 10 | 3/8 | 17.1 | 1.2 | 0.47 | 1.65 | 0.63 | 2.00 | 0.74 | 2.31 | 0.840 | 3.20 | 1.10 | – | – | – | – |

| 15 | 1/2 | 21.3 | 1.65 | 0.80 | 2.11 | 1.00 | 2.30 | 1.07 | 2.77 | 1.27 | 3.73 | 1.62 | 4.75 | 1.94 | 7.47 | 2.55 |

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 2.11 | 1.28 | 2.55 | 1.52 | 2.87 | 1.69 | 3.91 | 2.20 | 5.56 | 2.90 | 7.82 | 3.64 |

| 25 | 1 | 33.4 | 1.65 | 1.30 | 2.77 | 2.09 | 2.55 | 1.94 | 3.38 | 2.50 | 4.55 | 3.24 | 6.35 | 4.24 | 9.09 | 5.45 |

| 32 | 1.1/4 | 42.2 | 1.65 | 1.65 | 2.77 | 2.70 | 3.00 | 2.90 | 3.56 | 3.39 | 4.85 | 4.47 | 6.35 | 5.61 | 9.70 | 7.77 |

| 40 | 1.1/2 | 48.3 | 1.65 | 1.91 | 2.77 | 3.11 | 3.00 | 3.55 | 3.68 | 4.05 | 5.08 | 5.41 | 7.14 | 7.25 | 11.1 | 10.18 |

| 50 | 2 | 60.3 | 1.65 | 2.40 | 2.77 | 3.93 | 3.00 | 4.24 | 3.91 | 5.44 | 5.54 | 7.48 | 8.74 | 11.11 | 11.07 | 13.44 |

| 65 | 2.1/2 | 73.0 | 2.11 | 3.69 | 3.05 | 5.26 | 4.00 | 6.81 | 5.16 | 8.63 | 7.01 | 11.41 | 9.53 | 14.91 | 14.02 | 20.39 |

| 80 | 3 | 88.9 | 2.11 | 4.51 | 3.05 | 6.45 | 4.00 | 8.37 | 5.49 | 11.29 | 7.62 | 15.27 | 11.1 | 21.30 | 15.24 | 27.68 |

| 100 | 4 | 114.3 | 2.11 | 5.84 | 3.05 | 8.36 | 4.50 | 12.18 | 6.02 | 16.07 | 8.56 | 22.32 | 13.49 | 33.54 | 17.12 | 41.03 |

| 125 | 5 | 141.3 | 2.77 | 9.47 | 3.40 | 11.57 | 5.00 | 16.80 | 6.55 | 21.8 | 9.53 | 30.97 | 15.88 | 49.11 | 19.05 | 57.43 |

| 150 | 6 | 168.3 | 2.77 | 11.32 | 3.40 | 13.84 | 6.35 | 25.36 | 7.11 | 28.26 | 10.97 | 42.56 | 18.25 | 67.53 | 21.95 | 79.22 |

| 200 | 8 | 219.1 | 2.77 | 14.79 | 3.76 | 19.96 | 6.35 | 33.31 | 8.18 | 42.55 | 12.7 | 64.64 | 23.01 | 111.27 | 22.23 | 107.92 |

| 250 | 10 | 273.1 | 3.40 | 22.63 | 4.19 | 27.78 | 6.35 | 41.77 | 9.27 | 60.31 | 12.7 | 96.01 | 28.58 | 172.33 | 25.40 | 155.15 |

| 300 | 12 | 323.8 | 3.96 | 31.25 | 4.57 | 36.00 | 6.35 | 49.7 | 9.53 | 73.88 | 12.7 | 132.05 | 33.32 | 238.76 | 25.40 | 186.97 |

| 350 | 14 | 355.6 | 3.96 | 34.36 | 4.78 | 41.3 | 7.92 | 67.80 | 11.13 | 94.59 | ||||||

| 400 | 16 | 406.4 | 4.19 | 41.56 | 4.78 | 47.29 | 7.92 | 77.83 | 12.7 | 123.30 | ||||||

| 450 | 18 | 457.2 | 4.19 | 46.81 | 4.78 | 53.26 | 7.92 | 87.71 | 14.27 | 155.80 | ||||||

| 500 | 20 | 508.0 | 4.78 | 59.25 | 5.54 | 68.61 | 9.53 | 117.14 | 15.09 | 183.42 | ||||||

| 600 | 24 | 610.0s | 5.54s | 82.47 | 6.35 | 94.45 | 9.53 | 141.12 | 17.48 | 255.41 | ||||||

| Stainless Steel 904L Hydraulic Tubing | UNS N08904 Coiled Tube |

| ASME SB677 TP 904L ERW Tube | Stainless Steel 1.4539 Electropolished Tube |

| 904L SS Rectangular Tubing | ASTM B677 TP 904L CDW Tube |

| SS B677 TP904L Electropolish Tube | 904L Stainless Steel Capillary Tubing |

| Stainless Steel 1.4539 Small Diameter Tubing | ASME SB677 TP 904L ERW Tubing |

| ASTM B677 TP 904L High Pressure Tube | Stainless Steel 904L Tubing |

| UNS N08904 Tube | 904L Stainless Steel Round Tube |

| SS B677 TP904L EFW Tube | UNS N08904 Finned Tube |

Application of ASTM A213 TP904l Tube

- Automotive applications

- Aerospace industry

- Water treatment

- Marine applications

- HVAC systems

Packaging of Alloy 904L Condenser tubes

Customized packaging methods are implemented for steel tubes, taking into account their varying types and sizes. While we ensure proper packaging for typical pipe types, special attention is required during sealift handling and transportation to minimize potential harm due to movement and bending.

Frequently asked questions

What are the mechanical properties of ASTM B677 UNS N08904 Tube?

The mechanical properties of ASTM B677 UNS N08904 Tube include high tensile strength, good ductility, and excellent creep resistance, allowing them to withstand demanding conditions.

Are 904l Stainless Steel Tubing suitable for high-pressure applications?

Yes, 904l Stainless Steel Tubing are suitable for high-pressure applications, provided they meet the required specifications and are installed with appropriate fittings.

Can 904l Seamless Pipe be used in seawater environments?

904l Seamless Pipe exhibit good resistance to seawater environments, particularly in applications where high-temperature and corrosion resistance are crucial.

Are SS 904L ERW Tubes prone to thermal shock?

SS 904L ERW Tubes are generally resistant to thermal shock, but rapid temperature changes should be carefully managed to prevent any potential stress or damage.

How does the oxidation resistance of SS Grade 904l Round Tubing compare to other stainless steel grades?

SS Grade 904l Round Tubing offer excellent oxidation resistance, surpassing many other stainless steel grades