Stainless steel 304 Precision Tubes Supplier in India

The Stainless Steel Capillary Tube is a high precision measurement tube that is most commonly seen in measuring devices. Suppliers of SS Capillary Tubes propose using these tubes in important applications such as nuclear reactors, aircraft equipment, and so on. The 304 Stainless Steel Capillary Tube is required for the liquid chromatography equipment to work well. The capillary tubes have a continuous grain structure because they are constructed of several grades of stainless steel.

The SS Capillary Tube Seamless performs better than welded ones, which can cause pipe discontinuity. As a result, crevice corrosion and mechanical failures of the welded Stainless Steel HPLC Tubing may occur.

SS 304 Precision Tubing Supplier, we can help with all Grade 316 SS Needle tubing supply needs

The Stainless Steel 1/16 In. Capillary Tubing is constructed of a single piece of homogeneous steel. It has a grain structure that is continuous and uninterrupted. The 1/16 Capillary Tubing is appropriate for applications that require constant material along the length of the tubing. Weldings and mechanical fittings on Stainless Steel Needle Tubing can cause discontinuity, which can lead to crevice corrosion. Mechanical breakdowns can also result from discontinuity.The use of high-quality materials in the manufacture of SS micro tubing aids in the formation of a passive protective layer. It occurs on the surface when there is oxygen present. Because of these characteristics and benefits, the SS Evaporator Coil Capillary Tube is extensively utilized in a variety of applications such as HPCL tubing, hydraulic tubing, and so on.

Table of content

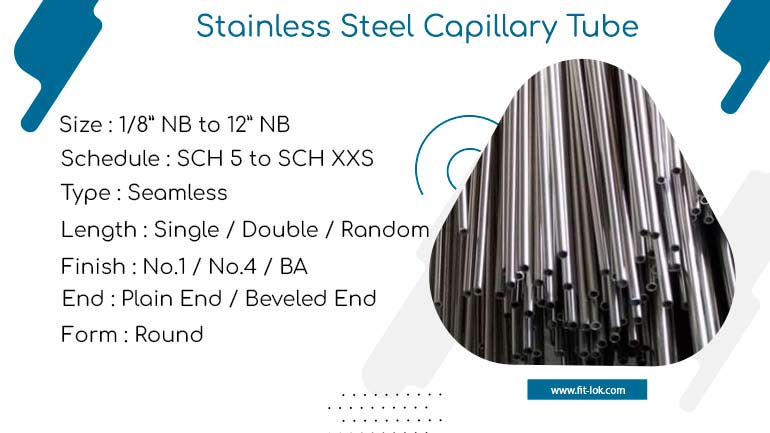

- Stainless steel capillary tube Specification

- Stainless Steel Hypodermic Tubing Types

- 304 SS capillary tube Wall Thickness

- SS 304 Precision Tubing Pressure Rating

- SS Needle tubing Chemical Compostion

- SS Evaporator Coil Capillary Tube Mechanical Properties

- Equivalent of Stainless Steel Capillary Tubing

| Material | SS 304, SS 304L, SS 316, SS 316L |

|---|---|

| Size Range | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Thickness | Schedule 5 to Schedule XXS |

| Wall Thickness | 0.08 To 0.2 mm |

| Form | Round, Strait, Hydraulic etc. |

| Outside Diameter | 0.3 To 12.0 mm |

| Finish | Bright Annealed, Pickled, Polished, Electrolytic Polished |

| Type | Semi Seamless, Welded, EFW, Seamless, ERW, Bead Removed |

| Mill Test Certificate | EN10204 3.1 |

304 stainless steel capillary tube

SS 304 Precision Tubing

Grade 316 SS Needle tubing

SS Evaporator Coil Capillary Tube

Stainless Steel Capillary Tubing

SS Needle Tubing

Our commitment to excellence has established us as the leading stockist and distributor for high-temperature SS Evaporator Coil Capillary Tube.

| Gauge | Ultra Thin Wall (UTW) mm | Outside Diameter Tolerance mm | Regular Wall (RW) mm | Extra Thin Wall (XTW) mm |

|---|---|---|---|---|

| 30 | 0.304 – 0.317 | 0.064 – 0.089 | ||

| 29 | o.330 – 0.342 | 0.064 – 0.089 | ||

| 28 | 0.355 – 0.368 | 0.076 – 0.102 | ||

| 27 | 0.406 – 0.419 | 0.089 – 0.115 | ||

| 26 | 0.457 – 0.469 | 0.089 – 0.114 | ||

| 25 | 0.508 – 0.520 | 0.115 – 0.140 | ||

| 24 | 0.051 – 0.102 | 0.558 – 0.571 | 0.114 – 0.140 | |

| 23 | 0.051 – 0.102 | 0.635 – 0.647 | 0.140 – 0.165 | |

| 22 | 0.051 – 0.102 | 0.711 – 0.723 | 0.140 – 0.165 | 0.077 – 0.102 |

| 21 | 0.051 – 0.102 | 0.812 – 0.825 | 0.140 – 0.165 | |

| 20 | 0.901 – 0.914 | 0.108 – 0.165 | ||

| 19 | 1.054 – 1.079 | 0.166 – 0.216 | 0.070 – 0.108 | |

| 18 | 0.051 – 0.102 | 1.257 – 1.282 | 0.191 – 0.241 | 0.083 – 0.121 |

| 17 | 0.057 – 0.102 | 1.460 – 1.485 | 0.177 – 0.229 | 0.083 – 0.127 |

| 16 | 0.070 – 0.121 | 1.638 – 1.663 | 0.204 – 0.254 | 0.096 – 0.133 |

| 15 | 0.070 – 0.121 | 1.816 – 1.841 | 0.204 – 0.254 | 0.096 – 0.134 |

| 14 | 0.076 – 0.134 | 2.082 – 2.133 | 0.216 – 0.292 | 0.114 – 0.165 |

| 13 | 2.387 – 2.438 | 0.267 – 0.343 | ||

| 12 | 2.743 – 2.749 | 0.267 – 0.321 | ||

| 11 | 3.023 – 3.073 | 0.293 – 0.368 | ||

| 10 | 0.216 – 0.292 | 3.378 – 3.429 | 0.318 – 0.394 |

| Outer Diameter in Inch | Collapse Pressure | Yield Strength | Tensile Strength | Wall Thickness in Inch | Working Pressure | Theoretical Burst Pressure | Theoretical Yield Point |

|---|---|---|---|---|---|---|---|

| 0.250 | 11,544 | 30,000 | 75,000 | 0.065 | 20,313 | 81,250 | 32,500 |

| 0.375 | 5,077 | 30,000 | 75,000 | 0.035 | 4,303 | 17,213 | 6,885 |

| 0.500 | 3,906 | 30,000 | 75,000 | 0.035 | 3,052 | 12,209 | 4,884 |

| 0.375 | 6,816 | 30,000 | 75,000 | 0.049 | 6,634 | 26,534 | 10,614 |

| 0.500 | 2,316L | 30,000 | 75,000 | 0.020 | 1,630 | 6,522 | 2,609 |

| 0.500 | 3,172 | 30,000 | 75,000 | 0.028 | 2,365 | 9,459 | 3,784 |

| 0.250 | 9,455 | 30,000 | 75,000 | 0.049 | 12,089 | 48,355 | 19,342 |

| 0.500 | 5,316L | 30,000 | 75,000 | 0.049 | 4,571 | 18,284 | 7,313 |

| 0.250 | 7,224 | 30,000 | 75,000 | 0.035 | 7,292 | 29,167 | 11,667 |

| 0.500 | 6,786 | 30,000 | 75,000 | 0.065 | 6,588 | 26,351 | 10,541 |

| 0.375 | 8,597 | 30,000 | 75,000 | 0.065 | 9,949 | 39,796 | 15,918 |

| 0.500 | 8,307 | 30,000 | 75,000 | 0.083 | 9,319 | 37,275 | 14,910 |

| 0.625 | 2,568 | 30,000 | 75,000 | 0.028 | 1,845 | 7,381 | 2,953 |

| 0.625 | 1,859 | 30,000 | 75,000 | 0.020 | 1,282 | 5,128 | 2,051 |

| 0.625 | 3,172 | 30,000 | 75,000 | 0.035 | 2,365 | 9,459 | 3,784 |

| 0.625 | 4,335 | 30,000 | 75,000 | 0.049 | 3,487 | 13,947 | 5,579 |

| 0.625 | 5,591 | 30,000 | 75,000 | 0.065 | 4,924 | 19,697 | 7,879 |

| 0.625 | 6,910 | 30,000 | 75,000 | 0.083 | 6,781 | 27,124 | 10,850 |

| 0.250 | 5,967 | 30,000 | 75,000 | 0.028 | 5,412 | 21,649 | 8,660 |

| 0.625 | 7,734 | 30,000 | 75,000 | 0.095 | 8,190 | 32,759 | 13,103 |

| 0.625 | 8,639 | 30,000 | 75,000 | 0.109 | 10,043 | 40,172 | 16,069 |

| 0.750 | 2,156 | 30,000 | 75,000 | 0.028 | 1,513 | 6,052 | 2,421 |

| 0.750 | 2,669 | 30,000 | 75,000 | 0.035 | 1,930 | 7,721 | 3,088 |

| 0.750 | 3,664 | 30,000 | 75,000 | 0.049 | 2,818 | 11,273 | 4,509 |

| 0.750 | 4,749 | 30,000 | 75,000 | 0.065 | 3,931 | 15,726 | 6,290 |

| 0.750 | 5,905 | 30,000 | 75,000 | 0.083 | 5,330 | 21,318 | 8,527 |

| 0.750 | 6,637 | 30,000 | 75,000 | 0.095 | 6,362 | 25,446 | 10,179 |

| 0.750 | 7,453 | 30,000 | 75,000 | 0.109 | 7,683 | 30,733 | 12,293 |

| 0.875 | 1,340 | 30,000 | 75,000 | 0.020 | 898 | 3,593 | 1,437 |

| 0.250 | 4,416 | 30,000 | 75,000 | 0.020 | 3,571 | 14,286 | 5,714 |

| 0.875 | 1,859 | 30,000 | 75,000 | 0.028 | 1,282 | 5,128 | 2,051 |

| 0.875 | 2,316L | 30,000 | 75,000 | 0.035 | 1,630 | 6,522 | 2,609 |

| 0.875 | 3,172 | 30,000 | 75,000 | 0.049 | 2,365 | 9,459 | 3,784 |

| 0.875 | 4,126 | 30,000 | 75,000 | 0.065 | 3,272 | 13,087 | 5,235 |

| 0.875 | 5,152 | 30,000 | 75,000 | 0.083 | 4,390 | 17,560 | 7,024 |

| 0.375 | 3,029 | 30,000 | 75,000 | 0.020 | 2,239 | 8,955 | 3,582 |

| 0.875 | 6,543 | 30,000 | 75,000 | 0.109 | 6,221 | 24,886 | 9,954 |

| 0.875 | 7,100 | 30,000 | 75,000 | 0.120 | 7,087 | 28,346 | 11,339 |

| 1.000 | 1,633 | 30,000 | 75,000 | 0.028 | 1,112 | 4,449 | 1,780 |

| 1.000 | 2,027 | 30,000 | 75,000 | 0.035 | 1,411 | 5,645 | 2,258 |

| 1.000 | 3,647 | 30,000 | 75,000 | 0.065 | 2,802 | 11,207 | 4,483 |

| 1.000 | 4,567 | 30,000 | 75,000 | 0.083 | 3,732 | 14,928 | 5,971 |

| 1.000 | 5,159 | 30,000 | 75,000 | 0.095 | 4,398 | 17,593 | 7,037 |

| 1.000 | 6,336 | 30,000 | 75,000 | 0.120 | 5,921 | 23,684 | 9,474 |

| 1.000 | 6,963 | 30,000 | 75,000 | 0.134 | 6,865 | 27,459 | 10,984 |

| 0.375 | 4,145 | 30,000 | 75,000 | 0.028 | 3,292 | 13,166 | 5,266 |

| 1.250 | 1,633 | 30,000 | 75,000 | 0.035 | 1,112 | 4,449 | 1,780 |

| 2.000 | 3,384 | 30,000 | 75,000 | 0.120 | 2,557 | 10,227 | 4,091 |

| 1.250 | 2,260 | 30,000 | 75,000 | 0.049 | 1,595 | 6,380 | 2,552 |

| 1.250 | 2,958 | 30,000 | 75,000 | 0.065 | 2,176 | 8,705 | 3,482 |

| 1.000 | 5,827 | 30,000 | 75,000 | 0.109 | 5,227 | 20,908 | 8,363 |

| 1.250 | 3,719 | 30,000 | 75,000 | 0.083 | 2,871 | 11,485 | 4,594 |

| 1.250 | 4,213 | 30,000 | 75,000 | 0.095 | 3,361 | 13,443 | 5,377 |

| 1.250 | 4,776 | 30,000 | 75,000 | 0.109 | 3,961 | 15,843 | 6,337 |

| 1.000 | 2,796 | 30,000 | 75,000 | 0.049 | 2,037 | 8,149 | 3,259 |

| 1.250 | 5,207 | 30,000 | 75,000 | 0.120 | 4,455 | 17,822 | 7,129 |

| 1.250 | 5,742 | 30,000 | 75,000 | 0.134 | 5,117 | 20,468 | 8,187 |

| 1.500 | 1,367 | 30,000 | 75,000 | 0.035 | 918 | 3,671 | 1,469 |

| 1.500 | 1,896 | 30,000 | 75,000 | 0.049 | 1,311 | 5,243 | 2,097 |

| 1.500 | 2,487 | 30,000 | 75,000 | 0.065 | 1,779 | 7,117 | 2,847 |

| 1.500 | 3,559 | 30,000 | 75,000 | 0.095 | 2,719 | 10,878 | 4,351 |

| 1.750 | 2,146 | 30,000 | 75,000 | 0.065 | 1,505 | 6,019 | 2,407 |

| 1.500 | 4,043 | 30,000 | 75,000 | 0.109 | 3,188 | 12,754 | 5,101 |

| 0.750 | 8,064 | 30,000 | 75,000 | 0.120 | 8,824 | 35,294 | 14,118 |

| 1.500 | 4,881 | 30,000 | 75,000 | 0.134 | 4,079 | 16,315 | 6,526 |

| 1.500 | 5,336 | 30,000 | 75,000 | 0.148 | 4,610 | 18,439 | 7,375 |

| 1.750 | 1,176 | 30,000 | 75,000 | 0.035 | 781 | 3,125 | 1,250 |

| 1.750 | 1,434 | 30,000 | 75,000 | 0.049 | 966 | 3,864 | 1,546 |

| 1.750 | 2,711 | 30,000 | 75,000 | 0.083 | 1,965 | 7,860 | 3,144 |

| 1.750 | 3,080 | 30,000 | 75,000 | 0.095 | 2,284 | 9,135 | 3,654 |

| 1.750 | 3,832 | 30,000 | 75,000 | 0.120 | 2,980 | 11,921 | 4,768 |

| 1.500 | 3,136 | 30,000 | 75,000 | 0.083 | 2,333 | 9,333 | 3,733 |

| 1.750 | 4,242 | 30,000 | 75,000 | 0.134 | 3,391 | 13,563 | 5,425 |

| 1.750 | 4,645 | 30,000 | 75,000 | 0.148 | 3,817 | 15,268 | 6,107 |

| 0.875 | 5,807 | 30,000 | 75,000 | 0.095 | 5,201 | 20,803 | 8,321 |

| 2.000 | 1,032 | 30,000 | 75,000 | 0.035 | 680 | 2,720 | 1,088 |

| 1.500 | 4,416 | 30,000 | 75,000 | 0.120 | 3,571 | 14,286 | 5,714 |

| 1.500 | 3,136 | 30,000 | 75,000 | 0.083 | 2,333 | 9,333 | 3,733 |

| 2.000 | 1,434 | 30,000 | 75,000 | 0.049 | 966 | 3,864 | 1,546 |

| 2.000 | 1,887 | 30,000 | 75,000 | 0.065 | 1,303 | 5,214 | 2,086 |

| 2.000 | 2,387 | 30,000 | 75,000 | 0.083 | 1,697 | 6,788 | 2,715 |

| 2.000 | 2,715 | 30,000 | 75,000 | 0.095 | 1,968 | 7,873 | 3,149 |

| 2.000 | 3,092 | 30,000 | 75,000 | 0.109 | 2,294 | 9,175 | 3,670 |

| 1.750 | 5,124 | 30,000 | 75,000 | 0.165 | 4,357 | 17,430 | 6,972 |

| 2.000 | 3,751 | 30,000 | 75,000 | 0.134 | 2,901 | 11,605 | 4,642 |

| 1.750 | 3,504 | 30,000 | 75,000 | 0.109 | 2,668 | 10,672 | 4,213 |

| 2.000 | 4,111 | 30,000 | 75,000 | 0.148 | 3,257 | 13,028 | 5,211 |

| 2.000 | 4,542 | 30,000 | 75,000 | 0.165 | 3,705 | 14,820 | 5,928 |

We can provide Stainless Steel Capillary Tubing in basically any size

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| 304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Material | Heat | Tensile Strength | Temperure | Yield Strength | Elongation |

|---|---|---|---|---|---|

| Treatment | Ksi (MPa), Min. | Min. | Ksi | ||

| º F(º C) | |||||

| TP304 | Solution | 75(515) | 1900 (1040) | 30(205) | 35 |

| TP304L | Solution | 70(485) | 1900 (1040) | 25(170) | 35 |

| TP316 | Solution | 75(515) | 1900(1040) | 30(205) | 35 |

| TP316L | Solution | 70(485) | 1900(1040) | 25(170) | 35 |

We invite you to contact us in order to obtain a fair and reasonable price for high Stainless Steel Hypodermic Tubing.

| Grade | UNS NO | DIN/WERKSTOFF |

|---|---|---|

| 304 | S30400 | 1.4301 |

| 304L | S30403 | 1.4306 |

| 316 | S31600 | 1.4436 |

| 316L | S31603 | 1.4404 |

Application of Stainless Steel Needle Tubing

- Automobile Industries

- Buildings & Infrastructure

- Chemical

- Construction

- Gas & Oil Industries

- Industry Appliances

- Mechanical Equipment

- Transportation

Packaging of SS HPLC Tubing

The packaging techniques for steel tubes differ based on their type and size. While we offer packaging methods for common pipe types, extra precautions may be necessary in certain instances to safeguard against damages caused by wiggling and bending during sealift handling and transportation.

Frequently asked questions

What is the typical diameter range for SS capillary tubes?

Diameter range of these tubes are varies from 0.3 mm to 25 mm.

How are 304 stainless steel capillary tube manufactured?

These are manufactured using seamless drawing process or pilgering process.

Tolerance range of SS 304 Precision Tubing

Tolerance range of these tubes are between ±0.05 mm to ±0.1 mm depending on diameter.

What is the ASTM standard for SS Evaporator Coil Capillary Tube

ASTM Standard for SS Capillary Tube is ASTM A269.