Are you looking for stainless steel 316 coiled tube supplier in India

The Stainless Steel Coiled Tubing is a long metal tube that is supplied on a huge reel as a spool. They are well-known for their superior corrosion and oxidation resistance in a variety of conditions. Stainless Steel Tubing Coils are commonly used in drilling operations, wells, hydraulic fracturing, and other applications. They are beneficial in applications involving the pumping of fluids under high salinity and high temperature environments. The stainless steel coil tubing heat exchanger is suited for use in unit heaters, condensers, boiler air preheating, and other applications. Flexibility, high efficiency, and minimal pressure drop are three of the main reasons for the popularity of Stainless Steel Coil Tube.

Find a reliable 304 stainless steel coil tubing supplier offering a wide range of sizes to meet your specific project requirements

The surface of the Soft Stainless Steel Tubing has a highly polished appearance. The soft Stainless Steel Coil Tubing has high strength and corrosion resistance. Because the SS 316 Super Long Coiled Tubing is machinable, it may be easily molded or bent. They are delivered in a variety of dimensions based on the client’s specifications. The 304 stainless steel coil tubing comes in sizes ranging from 0.5mm to 2.5mm.

Annealing in a bright light The annealing process in a controlled atmosphere (a vacuum or inert gas environment) is referred to as 1 inch stainless steel coil tubing. Bright annealing the 1 inch stainless steel tubing coil reduces oxidation on their surface, resulting in a brighter surface. It also thins off the oxide layer. Bright Annealed coiled tubing has a bright and reflective look, yet it may contain minor flaws such as cloudiness. This treatment is recommended by stainless steel tube coils manufacturers as an alternative to the buffed mirror finish.

Table of content

| Standard | ASTM A213/ASME SA213, ASTM A269 /ASME SA 269, EN10216-5, JIS G3463 |

| Tolerance | D4/T4 |

| Strength | Burst, Tensile |

| END | Plain End |

| Soundness Tests | Ultrasonic, Eddy Current |

| Hardness | Micro, Rockwell |

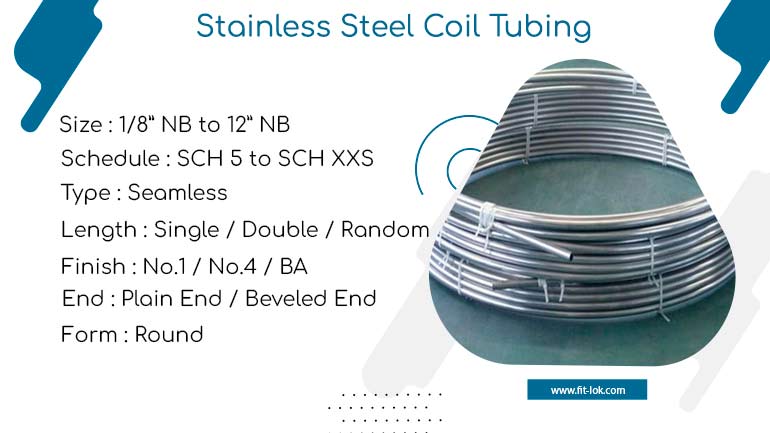

stainless steel coil tubing

ss tube coil

304 stainless steel coil tubing

316 Stainless steel Coiled Tube

SS 316 Welded Coil Tubing

Welded Stainless Steel Coil tube

The smooth internal surface of our SS 316 Welded Coil Tubing minimizes friction and ensures efficient fluid flow.

- Upgrading security

- lower your expenses

- a small container for storage and transportation

| Grade | Carbon | Magnesium | Phosphorus | sulfur | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| 304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

When it comes to sourcing high-temperature Welded Stainless Steel Coil tube, industry professionals trust our leading stockist and distributor services.

| Grade | Yield Strength | Temperure | Elongation | Tensile Strength | Heat |

|---|---|---|---|---|---|

| Ksi (MPa), Min. | Min. º F(º C) | Ksi (MPa), Min. | Treatment | ||

| TP304 | 30(205) | 1900 (1040) | 35 | 75(515) | Solution |

| TP304L | 25(170) | 1900 (1040) | 35 | 70(485) | Solution |

| TP316 | 30(205) | 1900(1040) | 35 | 75(515) | Solution |

| TP316L | 25(170) | 1900(1040) | 35 | 70(485) | Solution |

| Coil Tube Sizes | Thickness in MM | Diameter in MM | Weight in Kg/m |

|---|---|---|---|

| 6×1.0×6 | 2.0 | 27 | 1.04 |

| 6×1.0×2 | 2.0 | 20 | 0.60 |

| 6×1.0×4 | 2.0 | 24 | 0.82 |

| 6×1.0×5 | 2.0 | 25 | 0.90 |

| 6×1.0×1 | 1.0 | 8 | 0.15 |

| 6×1.0×7 | 2.0 | 27 | 1.15 |

| 6×1.0×3 | 2.0 | 21 | 0.75 |

| 6×1.0×8 | 2.2 | 32 | 1.40 |

| 8×1.0×1 | 1.0 | 10 | 0.28 |

| 8×1.0×2 | 1.8 | 24 | 0.89 |

Ensure the ss tube coil you select have the appropriate pressure rating to handle the desired fluid or gas pressures

| Outer Diameter | Size in Inch | Length | Wall Thickness |

|---|---|---|---|

| 0.250 | .250 X .065 W | 1,668 | 0.065 |

| 0.375 | .375 X .049 W | 1,225 | 0.049 |

| 0.375 | .375 X .065 W | 995 | 0.065 |

| 0.500 | .500 X .035 W | 1,232 | 0.035 |

| 0.500 | .500 X .049 W | 909 | 0.049 |

| 0.375 | .375 X .035 W | 1,685 | 0.035 |

| 0.500 | .500 X .049 W (15 Ra Max) | 909 | 0.049 |

| 0.125 | .125 X .035 W | 6,367 | 0.035 |

| 0.250 | .250 X .035 W | 2,665 | 0.035 |

| 0.500 | .500 X .065 W | 708 | 0.065 |

| 0.375 | .375 X .035 W (15 Ra Max) | 1,685 | 0.035 |

| 0.750 | .750 X .049 W | 584 | 0.049 |

| 0.250 | .250 X .035 W (15 Ra Max) | 2,665 | 0.035 |

| 0.750 | .750 X .065 W | 450 | 0.065 |

| 6mm | 6 MM X 1 MM W | 2,610 | 1mm |

| 0.250 | .250 X .049 W | 2,036 | 0.049 |

| 8mm | 8 MM X 1 MM W | 1,863 | 1mm |

| 10mm | 10 MM X 1 MM W | 1,449 | 1mm |

| 12mm | 12 MM X 1 MM W | 1,188 | 1mm |

Application of Soft SS Tubing

- HVAC systems

- Water treatment

- Marine applications

- Aerospace industry

- Automotive applications

Packaging of SS Multi-core Coiled Tubing

The packaging techniques for steel tubes differ based on their type and size. While we offer packaging methods for common pipe types, extra precautions may be necessary in certain instances to safeguard against damages caused by wiggling and bending during sealift handling and transportation.

Frequently asked questions

What are the advantages of using ss tube coil?

ss tube coil offers excellent corrosion resistance, high strength, and the ability to withstand high temperatures and pressures.

What is the typical diameter range of 304 stainless steel coil tubing?

304 stainless steel coil tubing is available in a wide diameter range, typically ranging from 1/8 inch to 3/4 inch or even larger.

How is 316 Stainless steel Coiled Tube commonly manufactured? –

316 Stainless steel Coiled Tube is commonly manufactured by cold drawing or cold rolling stainless steel strips into a seamless tube shape.

What are the typical applications of SS 316 Welded Coil Tubing?

SS 316 Welded Coil Tubing finds applications in industries such as oil and gas, chemical processing, aerospace, and automotive, where precision tubing is required for fluid or gas transport.

Is Welded Stainless Steel Coil tube available in different grades?

Yes, Welded Stainless Steel Coil tube is available in various grades such as 304, 316, and 321, each offering specific corrosion resistance and mechanical properties suitable for different applications.