Leading SS 316 Evaporator Coils Supplier in India

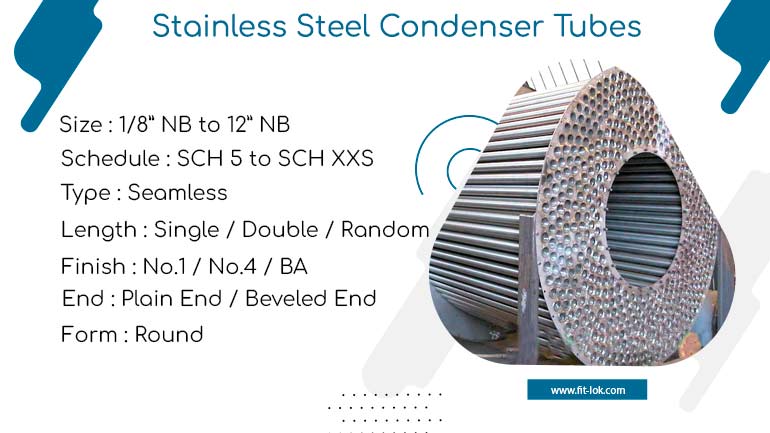

Stainless Steel Condenser Tubes are commonly used in heat exchangers. It is an important component of a condenser and evaporator refrigeration cycle, as well as a chiller for condensing steam in a surface condenser. The SUS 304L Tube And Fin Condenser has a variety of qualities depending on the grade of stainless steel used. It can have high tensile strength, good tensile strength, and so on. The grade is truly determined by the specifics of the application.

The SS Evaporator Tubes play an important part in the heating, cooling, and reheating of fluids and gases. ASTM A213 Superheater Tubes are available in a variety of sizes and can be customised to meet the needs of the client. They are frequently utilised in thermal power plants, nuclear power plants, and so on.

Partner with a SS Steam Condenser Tube supplier that has a comprehensive range of sizes, allowing for precise fitment in your projects

Manufacturers execute many types of tests on the SS Solution Anneal Condenser Tube, such as:

The leakage test aids in detecting any leaks in the tube. The eddy current test detects any discontinuities in the 316 Stainless Steel Double Tube Condenser. The condenser test confirms the thermal and hydraulic properties of the SS 304 Tube In Tube Condenser.Several further tests can be done on these tubes based on the application needs and customer demands.

Table of content

- Stainless Steel Condenser Tubes Specification

- SS Evaporator Tubes Types

- ASTM A249 Condensing Tube Pressure Rating

- ASTM A213 Superheater Tubes Advantages

- Stainless steel welded condenser coil tube Chemical Composition

- SS Steam Condenser Tube Mechanical Properties

- SS 316 Evaporator Coils Pressure Rating

- Stainless Steel 316l Condenser Tubes Wall Thickness

- SS Evaporator Tubes Size Chart

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

Stainless Steel 316L Evaporator Coils

Stainless Steel 304 Condenser Tubes

SS Steam Condenser Tube

Stainless Steel 316l Condenser Tubes

Stainless Steel Condenser Tubing

ASTM A249 Condensing Tube

| Tube Size in Inch | Tube Schedule | 200 | 500 | 100 | 650 | 400 | 300 | 700 | 600 | 750 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 40 | 2629 | 2019 | 3048 | 1867 | 2171 | 2362 | 1824 | 1924 | 1810 |

| 80 | 3634 | 2791 | 4213 | 2580 | 3002 | 3265 | 2528 | 2659 | 2501 | |

| 160 | 5296 | 4068 | 6140 | 3761 | 4375 | 4759 | 3684 | 3876 | 3646 | |

| 3 | 40 | 1558 | 1196 | 1806 | 1106 | 1287 | 1400 | 1084 | 1140 | 1072 |

| 80 | 2202 | 1691 | 2553 | 1564 | 1819 | 1979 | 1532 | 1612 | 1516 | |

| 160 | 3312 | 2544 | 3840 | 2352 | 2736 | 2976 | 2304 | 2424 | 2280 | |

| 10 | 40 | 840 | 645 | 974 | 596 | 694 | 755 | 584 | 615 | 578 |

| 80 | 1388 | 1066 | 1609 | 986 | 1147 | 1247 | 966 | 1016 | 956 | |

| 160 | 2714 | 2085 | 3147 | 1927 | 2242 | 2439 | 1880 | 1986 | 1868 | |

| 1 1/2 | 40 | 1947 | 1496 | 2257 | 1383 | 1608 | 1750 | 1354 | 1425 | 1340 |

| 80 | 2744 | 2108 | 3182 | 1949 | 2267 | 2466 | 1909 | 2009 | 1889 | |

| 160 | 3984 | 3060 | 4619 | 2829 | 3291 | 3580 | 2772 | 2916 | 2743 | |

| 2 | 40 | 1640 | 1260 | 1902 | 1165 | 1355 | 1474 | 1141 | 1201 | 1129 |

| 80 | 2369 | 1820 | 2747 | 1682 | 1957 | 2129 | 1648 | 1734 | 1631 | |

| 160 | 3880 | 2980 | 4499 | 2755 | 3205 | 3486 | 2699 | 2840 | 2671 | |

| 4 | 40 | 1321 | 1014 | 1531 | 938 | 1091 | 1187 | 919 | 967 | 909 |

| 80 | 1909 | 1466 | 2213 | 1355 | 1577 | 1715 | 1328 | 1397 | 1314 | |

| 160 | 3106 | 2386 | 3601 | 2206 | 2566 | 2791 | 2161 | 2273 | 2138 | |

| 6 | 40 | 1052 | 808 | 1219 | 747 | 869 | 945 | 732 | 770 | 724 |

| 80 | 1650 | 1267 | 1913 | 1172 | 1363 | 1483 | 1148 | 1208 | 1136 | |

| 160 | 2836 | 2179 | 3289 | 2014 | 2343 | 2549 | 1973 | 2076 | 1953 | |

| 5 | 40 | 1158 | 889 | 1342 | 822 | 956 | 1040 | 805 | 847 | 797 |

| 80 | 1709 | 1312 | 1981 | 1213 | 1411 | 1535 | 1189 | 1250 | 1176 | |

| 160 | 2945 | 2262 | 3414 | 2091 | 2433 | 2646 | 2049 | 2155 | 2027 | |

| 8 | 40 | 926 | 711 | 1073 | 657 | 765 | 832 | 644 | 678 | 637 |

| 80 | 1459 | 1121 | 1692 | 1036 | 1205 | 1311 | 1015 | 1068 | 1005 | |

| 160 | 2738 | 2103 | 3175 | 1944 | 2262 | 2460 | 1905 | 2004 | 1885 |

The excellent weldability of our Stainless Steel 316l Condenser Tubes allows for easy installation and secure connections.

- Loss of low pressure

- compact style, excellent effectiveness

- compensate for heat-related stressors

- reversible tube bundle

| Grade | Manganese | Phosphorus | Carbon | Sulfur | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| TP304 | 2 | 0.045 | 0.08 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| TP304L | 2 | 0.045 | 0.035 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| TP316 | 2 | 0.045 | 0.08 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| TP316L | 2 | 0.045 | 0.035 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Exporter of Stainless Steel Condenser Tubing, delivering superior quality products to global markets

| Grade | Gauge length | Tensile strength | Hardness | Yield strength | |

|---|---|---|---|---|---|

| bhn | rb | ||||

| 304 | 56 | 585 | 191 | 72 | 244 |

| 316 | 57 | 615 | 197 | 75 | 245 |

| 304L | 56 | 585 | 191 | 72 | 210 |

| 316L | 56 | 585 | 197 | 75 | 215 |

| Tube Size in Inch | Tube Schedule | 200 | 500 | 100 | 650 | 400 | 300 | 700 | 600 | 750 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 40 | 2629 | 2019 | 3048 | 1867 | 2171 | 2362 | 1824 | 1924 | 1810 |

| 80 | 3634 | 2791 | 4213 | 2580 | 3002 | 3265 | 2528 | 2659 | 2501 | |

| 160 | 5296 | 4068 | 6140 | 3761 | 4375 | 4759 | 3684 | 3876 | 3646 | |

| 3 | 40 | 1558 | 1196 | 1806 | 1106 | 1287 | 1400 | 1084 | 1140 | 1072 |

| 80 | 2202 | 1691 | 2553 | 1564 | 1819 | 1979 | 1532 | 1612 | 1516 | |

| 160 | 3312 | 2544 | 3840 | 2352 | 2736 | 2976 | 2304 | 2424 | 2280 | |

| 10 | 40 | 840 | 645 | 974 | 596 | 694 | 755 | 584 | 615 | 578 |

| 80 | 1388 | 1066 | 1609 | 986 | 1147 | 1247 | 966 | 1016 | 956 | |

| 160 | 2714 | 2085 | 3147 | 1927 | 2242 | 2439 | 1880 | 1986 | 1868 | |

| 1 1/2 | 40 | 1947 | 1496 | 2257 | 1383 | 1608 | 1750 | 1354 | 1425 | 1340 |

| 80 | 2744 | 2108 | 3182 | 1949 | 2267 | 2466 | 1909 | 2009 | 1889 | |

| 160 | 3984 | 3060 | 4619 | 2829 | 3291 | 3580 | 2772 | 2916 | 2743 | |

| 2 | 40 | 1640 | 1260 | 1902 | 1165 | 1355 | 1474 | 1141 | 1201 | 1129 |

| 80 | 2369 | 1820 | 2747 | 1682 | 1957 | 2129 | 1648 | 1734 | 1631 | |

| 160 | 3880 | 2980 | 4499 | 2755 | 3205 | 3486 | 2699 | 2840 | 2671 | |

| 4 | 40 | 1321 | 1014 | 1531 | 938 | 1091 | 1187 | 919 | 967 | 909 |

| 80 | 1909 | 1466 | 2213 | 1355 | 1577 | 1715 | 1328 | 1397 | 1314 | |

| 160 | 3106 | 2386 | 3601 | 2206 | 2566 | 2791 | 2161 | 2273 | 2138 | |

| 6 | 40 | 1052 | 808 | 1219 | 747 | 869 | 945 | 732 | 770 | 724 |

| 80 | 1650 | 1267 | 1913 | 1172 | 1363 | 1483 | 1148 | 1208 | 1136 | |

| 160 | 2836 | 2179 | 3289 | 2014 | 2343 | 2549 | 1973 | 2076 | 1953 | |

| 5 | 40 | 1158 | 889 | 1342 | 822 | 956 | 1040 | 805 | 847 | 797 |

| 80 | 1709 | 1312 | 1981 | 1213 | 1411 | 1535 | 1189 | 1250 | 1176 | |

| 160 | 2945 | 2262 | 3414 | 2091 | 2433 | 2646 | 2049 | 2155 | 2027 | |

| 8 | 40 | 926 | 711 | 1073 | 657 | 765 | 832 | 644 | 678 | 637 |

| 80 | 1459 | 1121 | 1692 | 1036 | 1205 | 1311 | 1015 | 1068 | 1005 | |

| 160 | 2738 | 2103 | 3175 | 1944 | 2262 | 2460 | 1905 | 2004 | 1885 |

| Wall Thickness Range in Inch | Gauge | Value in Inch |

|---|---|---|

| 0.112 through 0.122 | 11 | 0.12 |

| 0.066 through 0.074 | 15 | 0.072 |

| 0.031 through 0.035 | 20 | 0.035 |

| 0.038 through 0.042 | 19 | 0.042 |

| 0.025 through 0.029 | 22 | 0.028 |

| 0.044 through 0.049 | 18 | 0.049 |

| 0.053 through 0.058 | 17 | 0.058 |

| 0.101 through 0.111 | 12 | 0.109 |

| 0.140 through 0.150 | 9 | 0.148 |

| 0.060 through 0.065 | 16 | 0.065 |

| 0.087 through 0.097 | 13 | 0.095 |

| 0.126 through 0.136 | 10 | 0.134 |

| 0.075 through 0.085 | 14 | 0.083 |

| 0.157 through 0.167 | 8 | 0.165 |

| 0.175 through 0.185 | 7 | 0.18 |

Cut to size ASTM A249 Condensing Tube manufacturer and supplier in india at lowest price

| Sizes in Decimal | Sizes in mm | Sizes in Inch |

|---|---|---|

| .0625 | 1.59 | 1/16 |

| .3125 | 7.94 | 5/16 |

| .1875 | 4.76 | 3/16 |

| .1250 | 3.18 | 1/8 |

| .9375 | 23.81 | 15/16 |

| 1.50 | 38.10 | 1 1/2 |

| .2500 | 6.35 | 1/4 |

| .7500 | 19.05 | 3/4 |

| .5625 | 14.29 | 9/16 |

| 1.25 | 31.75 | 1 1/4 |

| 2.00 | 50.80 | 2 |

| .3750 | 9.53 | 3/8 |

| .4375 | 11.11 | 7/16 |

| .5000 | 12.70 | 1/2 |

| .6250 | 15.88 | 5/8 |

| .6875 | 17.46 | 11/16 |

| .8125 | 20.64 | 13/16 |

| .8750 | 22.23 | 7/8 |

| 1.00 | 25.40 | 1 |

Application of SS Steam Condenser Tube

- Construction and architecture

- Industrial machinery

- Power generation

- Textile industry

- Brewing equipment

Packaging of Stainless Steel 304 Condenser Tubes

Proper packaging of steel tubes is contingent on their specific type and dimensions. We have established packaging protocols for the most commonly used pipe varieties, yet additional care should be taken during sealift handling and transportation to avoid potential damages from movement.

Frequently asked questions

What are the advantages of using SS 304 Condenser Coil?

SS 304 Condenser Coil offer excellent corrosion resistance, high thermal conductivity, and resistance to fouling and scaling.

What is the typical diameter range of Stainless Steel 316L Evaporator Coils?

Stainless Steel 316L Evaporator Coils typically have diameters ranging from 6mm to 50mm or larger, depending on the specific condenser design and application.

How are Stainless Steel 304 Condenser Tubes commonly manufactured?

Stainless Steel 304 Condenser Tubes are commonly manufactured by seamless or welded processes, followed by heat treatment to ensure desired mechanical properties and corrosion resistance.

What are the typical applications of SS Steam Condenser Tube?

SS Steam Condenser Tube are widely used in industries such as power generation, chemical processing, HVAC, and refrigeration, where efficient heat transfer, corrosion resistance, and long-term durability are required for condensing operations.