SS 304 U Bend Tubing supplier in India

The Stainless Steel Heat Exchanger Tube is a type of tube that is utilised in high heat and pressure applications. They are primarily used to avoid all forms of welding connections while forming a reverse or a curve in different directions. The finned SA 213 Heat Exchanger Tube transfers heat from the system by employing fins on the pipe’s surface. The finned ASTM A213 heat exchanger tube’s construction contributes to a more effective heat transfer procedure than standard heat exchanger tubes.

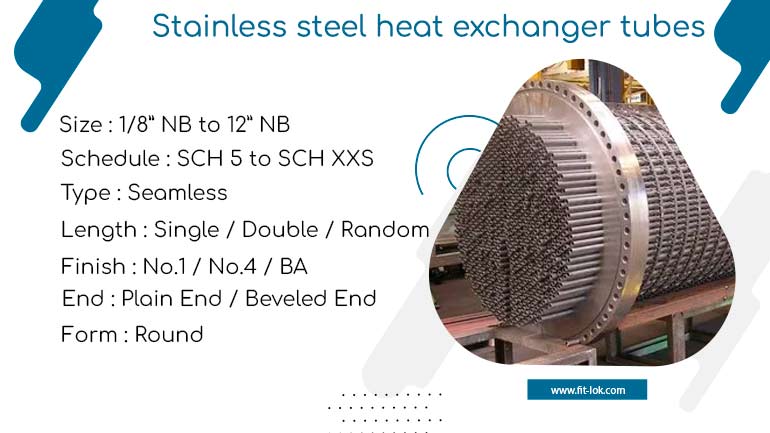

The SS Heat Exchanger Tubes come in a variety of sizes, dimensions, and material grades. They can be tailored to the needs of the client.

Our Stainless Steel Fin Tube Heat Exchanger are designed to withstand high temperatures and pressure, making them suitable for demanding industrial applications.

Heat exchanger tubes are made from several grades of stainless steel. The 304 SS Heat Exchanger Tube, for example, is extremely dependable and long-lasting. They have strong corrosion resistance and can reduce the deposition of various residues on the surface. Because the 316 SS heat exchanger tube is more corrosion resistant, the boilers are better protected. The Stainless Heat Exchanger Tube features durable properties, a simple design, and very inexpensive purchase and maintenance expenses. The heat transfer rate through Solution Anneal Heat Exchanger Tubing is relatively high, and the performance is excellent.

The fundamental advantage of SS Straight Tube Heat Exchangers is that they produce very little pressure loss throughout the operation. Because of their straight shape, SS 316L Heat Exchangers can be used in contaminated and viscous media without trouble. Straight 304L SS Heat Exchangers come in both upright and horizontal configurations. As a result, the straight Corrugated Heat Exchanger Tube provides improved overall performance and increased thermal conductivity at a lower cost.

Table of content

- Stainless Steel Heat Exchanger Tube Specification

- Stainless Steel Superheater Tube Types

- SA 213 Heat Exchanger Tubes Size Range

- Features of SS 304 U Bend Tubing

- Stainless Steel Fin Tube Heat Exchanger Chemical Compostion

- ASTM A213 heat exchanger tube Mechanical Properties

- Equivalent of SS Finned Tube Heat Exchanger

- 316l Stainless Steel Heat Exchanger Dimension Tolerance

| Specification | ASTM A269/ ASME SA 269, ASTM A249/ ASME SA 249, ASTM A789/ ASME SA 789 |

| Wall Thickness Range | 0.5 To 5 mm |

| Size Range | 6.53 to 127 mm |

| Tolerance | +/-0.05 Mm |

| Length | up to 20 Meter |

| Bending radius | 1.25 x Outer Diameter up to 1700mm |

| Processing Service | Welding, Cutting, Bending, Decoiling, Punching, Moulding |

| END | Beveled End, Plain End, Treaded |

| Delivery Condition | Bright Annealed, Annealed and Pickled, Cold Drawn, Polished, MF |

| Technique | Cold rolled, Hot rolled, Cold drawn, Extrusion Tube |

Stainless Steel Superheater Tube

TP316 Seamless U Tube

Stainless Steel Fin Tube Heat Exchanger

SS Finned Tube Heat Exchanger

316l Stainless Steel Heat Exchanger

304 Stainless Steel Heat Exchanger

- Range : 10 mm OD to 50.8 mm OD

- Wall Thickness : 0.70 mm to 8.00 mm

- Outer Diameter : 6.00 mm to 101.60 mm

- Length : up to 20 m (65.62 ft) Length & Customed Required Length

Choose a SS Finned Tube Heat Exchanger supplier that specializes in customized solutions, offering tailored sizes and pressure ratings for your unique needs

- according to specifications and applications

- solutions that are specialised for each application

- systems that are fully automated for effective and seamless functioning

- developed with cutting-edge software

| Grade | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Chromium | Molybdenum | Nickel | Nitrogen | Titanium | Iron | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 | Minimum | 18.0 | 8.0 | |||||||||

| Maximum | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| 304L | Minimum | 18.0 | 8.0 | |||||||||

| Maximum | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | Minimum | 0.04 | 18.0 | 8.0 | ||||||||

| Maximum | 0.010 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SS 310 | 0.015 | 2 | 0.015 | 0.020 | 0.015 | 24.00 26.00 | 0.10 | 19.00 21.00 | 54.7 | |||

| SS 310S | 0.08 | 2 | 1.00 | 0.045 | 0.030 | 24.00 26.00 | 0.75 | 19.00 21.00 | 53.095 | |||

| SS 310H | 0.04 0.10 | 2 | 1.00 | 0.045 | 0.030 | 24.00 26.00 | 19.00 21.00 | 53.885 | ||||

| 316 | Minimum | 16.0 | 2.03.0 | 10.0 | ||||||||

| Maximum | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316L | Minimum | 16.0 | 2.03.0 | 10.0 | ||||||||

| Maximum | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316TI | 0.08 | 10.00 14.00 | 2.0 | 0.045 | 0.030 | 16.00 18.00 | 0.75 | 2.00 3.00 | ||||

| 317 | 0.08 | 2 | 1 | 0.045 | 0.030 | 18.00 20.00 | 3.00 4.00 | 57.845 | ||||

| SS 317L | 0.035 | 2.0 | 1.0 | 0.045 | 0.030 | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 | |||

| SS 321 | 0.08 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 19.00 | 9.00 12.00 | 0.10 | 5(C+N) 0.70 | |||

| SS 321H | 0.04 0.10 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 19.00 | 9.00 12.00 | 0.10 | 4(C+N) 0.70 | |||

| 347/ 347H | 0.08 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 20.00 | 9.0013.00 | |||||

| 410 | Minimum | 11.5 | ||||||||||

| Maximum | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | Minimum | 23.0 | 0.10 | |||||||||

| Maximum | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| 904L | Minimum | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| Maximum | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

We are proud to be recognized as the leading stockist and distributor for high-temperature 316l Stainless Steel Heat Exchanger.

| Grade | Melting Point | Density | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 304/ 304L | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 304H | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 40 % |

| 310 / 310S / 310H | 1402 °C (2555 °F) | 7.9 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 40 % |

| 306/ 316H | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 316L | 1399 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 317 | 1400 °C (2550 °F) | 7.9 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 321 | 1457 °C (2650 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 347 | 1454 °C (2650 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 904L | 1350 °C (2460 °F) | 7.95 g/cm3 | Psi 32000 , MPa 220 | Psi 71000 , MPa 490 | 35 % |

| Grade | Unified Numbering System | Werkstoff Nr. | European Standards | JIS Standards | GOST | British Standard | AFNOR |

|---|---|---|---|---|---|---|---|

| 304 | S30400 | 1.4301 | X5CrNi18-10 | SUS 304 | 08Х18Н10 | 304S31 | Z7CN18‐09 |

| 304L | S30403 | 1.4306 / 1.4307 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 03Х18Н11 | 3304S11 | Z3CN18‐10 |

| 304H | S30409 | 1.4301 | |||||

| 310 | S31000 | 1.4841 | X15CrNi25-20 | SUS 310 | 20Ch25N20S2 | 310S24 | |

| 310S | S31008 | 1.4845 | X8CrNi25-21 | SUS 310S | 20Ch23N18 | 310S16 | |

| 310H | S31009 | ||||||

| 316 | S31600 | 1.4401 / 1.4436 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | Z7CND17‐11‐02 | |

| 316L | S31603 | 1.4404 / 1.4435 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 |

| 316H | S31609 | 1.4401 | |||||

| 316Ti | S31635 | 1.4571 | X6CrNiMoTi17-12-2 | SUS 316Ti | 08Ch17N13M2T | 320S31 | Z6CNDT17‐123 |

| 317 | S31700 | 1.4449 | SUS 317 | ||||

| 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 317L | |||

| 321 | S32100 | 1.4541 | X6CrNiTi18-10 | SUS 321 | |||

| 321H | S32109 | 1.4878 | X12CrNiTi18-9 | SUS 321H | |||

| 347 | S34700 | 1.4550 | X6CrNiNb18-10 | SUS 347 | 08Ch18N12B | ||

| 347H | S34709 | 1.4961 | X6CrNiNb18-12 | SUS 347H | |||

| 904L | N08904 | 1.4539 | X1NiCrMoCu25-20-5 | SUS 904L | STS 317J5L | 904S13 | Z2 NCDU 25-20 |

Exporter of 304 Stainless Steel Heat Exchanger with excellent pressure ratings, suitable for demanding applications in sectors like oil and gas, aerospace, and more

| Outer Diamewter | Specification | Tolerances | |||

|---|---|---|---|---|---|

| Outer Diameter | Wall Thickness | ||||

| Plus | Minus | Plus | Minus | ||

| Under 1.000 | ASTM-A-213 | .004 | .004 | 20% | 0% |

| 1.501 to 1.999 | Cold Finished Seamless | .008 | .008 | 22% | 0% |

| 4.001 to 5.000 | .015 | .025 | 22% | 0% | |

| 1.000 to 1.500 | ASME-SA-213 | .006 | .005 | 20% | 0% |

| 2.500 to 2.999 | Minimum Wall | .012 | .012 | 22% | 0% |

| 2.000 to 2.499 | Heat Exchanger Tube | .010 | .010 | 22% | 0% |

| 3.000 to 4.000 | .015 | .015 | 22% | 0% | |

Application of Stainless Heat Exchanger Tube

- Industrial machinery

- Textile industry

- Brewing equipment

- Construction and architecture

- Power generation

Packaging of 304 Stainless Steel Heat Exchanger Tube

Different packaging techniques are employed based on the type and size of steel tubes to guarantee secure transportation. While we offer packaging guidelines for common pipe types, we stress the importance of extra precautions during sealift handling and transportation to protect against damages resulting from movement and bending.

Frequently asked questions

What are the advantages of using Stainless Steel Superheater Tube?

Stainless Steel Superheater Tube offer excellent corrosion resistance, high thermal conductivity, and the ability to withstand high temperatures and pressures.

What is the typical diameter range of TP316 Seamless U Tube?

TP316 Seamless U Tube typically have diameters ranging from 6mm to 50mm or larger, depending on the specific heat exchanger design and application.

How are Stainless Steel Fin Tube Heat Exchanger commonly manufactured?

Stainless Steel Fin Tube Heat Exchanger are commonly manufactured by seamless or welded processes, followed by heat treatment to ensure desired mechanical properties and corrosion resistance.

What are the typical applications of SS Finned Tube Heat Exchanger?

SS Finned Tube Heat Exchanger are extensively used in industries such as chemical processing, oil and gas, power generation, and HVAC, where efficient heat transfer and corrosion resistance are essential.