One of the best SS 304 box tube supplier in India

Stainless steel alloys are broadly categorised into four classes, with the austenitic class being the most prevalent. Because stainless steel alloys have an FCC (Face centre cubic) microstructure. FCC microstructure alloys are typically packed very closely together. Because the crystals are so close together, the alloy is more ductile. Because the alloy has a higher amount of ductility, it may be formed into odd shapes such as Stainless Steel Rectangular Tubing.

Exporter of high-quality ss 304 rectangular tube, providing efficient shipping and delivery services to meet global demand

Because the tubing requirements for each alloy varied, so do the grades used to create them. Additionally, the Stainless Steel Rectangular Tubing Dimensions used to manufacture said tubing will differ. The dimensions will also include the thickness of the wall, the length, and the diameter or circumference. The most commonly used Austenitic classes are grade 304 and class 316. While grade 304 Stainless Steel Rectangular Tube is the most cost-effective option, grade 316, often known as marine grade steel, is a more robust option. The inclusion of molybdenum in the alloy of Stainless Steel Rectangular Tubing 316 results in an improvement in strength.

The addition of molybdenum to an alloy improves the material’s characteristics. For example, the alloy for grade 316 Stainless Steel Rectangular Tube would be more resistant to pitting and crevice corrosion than grade 304.

Table of content

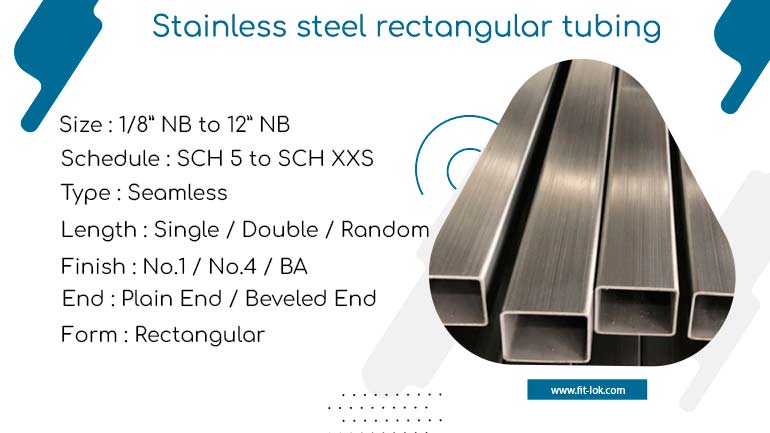

- Stainless steel rectangular tubing Specification

- Types of Stainless steel rectangular box section

- SS 304 box tube Tolerance

- SS 304 rectangular tube Weight chart

- Sizes of 304 stainless rectangle tube

- Polished stainless steel rectangular tubing Chemical Composition

- SS rectangular box Mechanical Properties

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

ss rectangular tube

stainless steel rectangular hollow section

316 stainless steel rectangular tubing

stainless steel box tubing

304 stainless steel rectangular tube

ss 304 rectangular tube

High-temperature polished stainless steel rectangular tubing are our specialty, and we excel as the leading stockist and distributor in the market.

| Nominal Pipe Size Designator | Permissible Variations in Outside Diameter | |

|---|---|---|

| Over In. | Under In. | |

| Over 8 to 18, Include | 3/23 (0.093) | 1/32 (0.031) |

| Over 1-1/2 to 4, Include | 1/32 (0.031) | 1/32 (0.031) |

| 1/8 to 1-1/2, Include | 1/64 (0.015) | 1/32 (0.031) |

| Over 4 to 8, Include | 1/16 (0.062) | 1/32 (0.031) |

| Nominal Pipe Size | Outside Diameter | Wall Thickness | Weight | Weight | |||

| Inch | mm | Schedule | Inch | mm | Lb/ft | kg/Mtr | |

| 1 1/2 | 1.900 | 48 | 40 STD | 0.145 | 3.683 | 2.718 | 4.048 |

| 80 STD | 0.200 | 5.080 | 3.361 | 5.409 | |||

| 1/2 | 0.840 | 21 | 40 STD | 0.109 | 2.769 | 0.851 | 1.268 |

| 80 STD | 0.147 | 3.734 | 1.088 | 1.621 | |||

| 1 1/4 | 1.660 | 42 | 40 STD | 0.140 | 3.556 | 2.273 | 3.385 |

| 80 STD | 0.191 | 4.851 | 2.997 | 4.464 | |||

| 1 | 1.315 | 33 | 40 STD | 0.133 | 3.378 | 1.679 | 2.501 |

| 80 STD | 0.179 | 4.547 | 2.172 | 3.325 | |||

| 8 | 8.625 | 219 | 0.188 | 4.775 | 16.940 | 25.233 | |

| 0.203 | 5.156 | 18.259 | 27.198 | ||||

| 0.219 | 5.563 | 19.661 | 29.286 | ||||

| 20 | 0.250 | 6.350 | 22.361 | 33.308 | |||

| 30 | 0.277 | 7.036 | 24.696 | 36.786 | |||

| 40 | 0.322 | 8.179 | 28.554 | 42.352 | |||

| 0.375 | 9.525 | 33.041 | 49.216 | ||||

| 60 | 0.406 | 10.312 | 35.638 | 53.085 | |||

| 80 XHY | 0.500 | 12.700 | 43.388 | 64.627 | |||

| 2 | 2.375 | 60 | 40 STD | 0.154 | 3.912 | 3.653 | 5.441 |

| 80 STD | 0.218 | 5.537 | 5.022 | 7.480 | |||

| 2 1/2 | 2.875 | 73 | 40 STD | 0.203 | 5.516 | 5.793 | 8.629 |

| 80 STD | 0.276 | 7.010 | 7.661 | 11.411 | |||

| 4 | 4.500 | 114 | 0.237 | 6.020 | 10.790 | 16.073 | |

| 0.337 | 8.560 | 14.983 | 22.318 | ||||

| 6 | 6.625 | 168 | 0.188 | 4.775 | 12.924 | 19.252 | |

| 0.203 | 5.516 | 13.923 | 20.739 | ||||

| 0.219 | 5.563 | 14.983 | 22.318 | ||||

| 0.250 | 6.350 | 17.021 | 25.354 | ||||

| 40 STD | 0.280 | 7.112 | 18.974 | 58.263 | |||

| 0.312 | 7.925 | 21.036 | 31.334 | ||||

| 0.375 | 9.525 | 25.031 | 37.285 | ||||

| 80 XHY | 0.432 | 10.973 | 28.573 | 42.561 | |||

| 0.500 | 12.700 | 32.708 | 48.719 | ||||

| 20 | 20.000 | 508 | 0.250 | 6.350 | 52.733 | 78.547 | |

| 0.282 | 7.163 | 59.386 | 88.458 | ||||

| 0.312 | 7.925 | 65.604 | 97.719 | ||||

| 20 STD | 0.375 | 9.525 | 78.598 | 117.075 | |||

| 0.438 | 11.125 | 91.508 | 136.305 | ||||

| 30 XHY | 0.500 | 12.700 | 104.130 | 155.106 | |||

| 40 | 0.594 | 15.088 | 123.110 | 183.378 | |||

| 0.625 | 15.875 | 129.328 | 192.640 | ||||

| 0.688 | 17.475 | 141.901 | 211.368 | ||||

| 10 | 10.750 | 273 | 0.188 | 4.775 | 21.207 | 31.588 | |

| 0.219 | 5.563 | 24.631 | 36.689 | ||||

| 20 | 0.250 | 6.350 | 28.035 | 41.759 | |||

| 30 | 0.307 | 7.798 | 34.240 | 51.002 | |||

| 0.344 | 8.738 | 38.231 | 56.946 | ||||

| 40 STD | 0.365 | 9.271 | 40.483 | 63.301 | |||

| 0.438 | 11.125 | 48.238 | 71.852 | ||||

| 60 XHY | 0.500 | 12.700 | 54.735 | 81.530 | |||

| 80 | 0.594 | 15.088 | 64.429 | 95.969 | |||

| 42 | 42.000 | 1067 | 0.312 | 7.925 | 138.911 | 206.914 | |

| STD | 0.375 | 9.525 | 166.708 | 248.319 | |||

| XHY | 0.500 | 12.700 | 221.610 | 33.097 | |||

| 0.750 | 19.050 | 330.413 | 492.163 | ||||

| 12 | 12.750 | 324 | 0.188 | 4.775 | 25.222 | 37.570 | |

| 0.219 | 5.563 | 29.309 | 43.657 | ||||

| 0.250 | 6.350 | 33.375 | 49.713 | ||||

| 0.281 | 7.137 | 37.420 | 55.739 | ||||

| 0.312 | 7.925 | 41.445 | 61.735 | ||||

| 0.375 | 9.525 | 49.562 | 73.824 | ||||

| 0.406 | 10.312 | 53.525 | 79.727 | ||||

| 0.500 | 12.700 | 65.415 | 97.438 | ||||

| 0.562 | 14.275 | 73.154 | 108.966 | ||||

| 3 | 3.500 | 89 | 40 STD | 0.216 | 5.486 | 7.576 | 11.284 |

| 80 STD | 0.300 | 7.620 | 10.253 | 15.272 | |||

| 14 | 14.000 | 356 | 0.188 | 4.775 | 27.732 | 41.308 | |

| 0.219 | 5.563 | 32.233 | 48.012 | ||||

| 20 | 0.250 | 6.350 | 36.713 | 54.685 | |||

| 0.281 | 7.137 | 41.172 | 61.327 | ||||

| 0.312 | 7.925 | 45.611 | 67.939 | ||||

| STD | 0.375 | 9.525 | 54.568 | 81.281 | |||

| 40 | 0.438 | 11.125 | 63.441 | 94.498 | |||

| XHY | 0.500 | 12.700 | 72.090 | 107.381 | |||

| 0.625 | 15.875 | 89.278 | 132.983 | ||||

| 16 | 16.000 | 406 | 0.188 | 4.775 | 21.748 | 47.290 | |

| 0.219 | 5.563 | 36.910 | 54.980 | ||||

| 10 | 0.250 | 6.350 | 42.053 | 62.639 | |||

| 0.281 | 7.137 | 47.174 | 70.268 | ||||

| 20 | 0.312 | 7.925 | 52.275 | 77.866 | |||

| 0.344 | 8.738 | 57.519 | 85.677 | ||||

| 30

STD |

0.375 | 9.525 | 62.578 | 93.213 | |||

| 0.438 | 11.125 | 72.797 | 108.433 | ||||

| 40

XHY |

0.500 | 12.700 | 82.770 | 123.289 | |||

| 18 | 18.000 | 457 | 0.219 | 5.563 | 41.588 | 61.948 | |

| 0.250 | 6.350 | 47.393 | 70.593 | ||||

| 0.281 | 7.137 | 53.176 | 79.208 | ||||

| 20 | 0.312 | 7.925 | 58.939 | 87.792 | |||

| STD | 0.375 | 9.525 | 70.588 | 105.144 | |||

| 30 | 0.438 | 11.125 | 82.152 | 122.369 | |||

| XHY | 0.500 | 12.700 | 93.450 | 139.198 | |||

| 40 | 0.562 | 14.275 | 104.666 | 155.904 | |||

| 0.625 | 15.875 | 115.978 | 172.754 | ||||

| 24 | 24.000 | 610 | 0.250 | 6.350 | 63.413 | 94.456 | |

| 0.281 | 7.137 | 71.183 | 106.029 | ||||

| 0.312 | 7.925 | 18.932 | 117.573 | ||||

| 20 STD | 0.375 | 9.525 | 64.618 | 140.938 | |||

| 0.438 | 11.125 | 110.219 | 164.176 | ||||

| XHY | 0.500 | 12.700 | 125.490 | 186.923 | |||

| 0.625 | 15.875 | 156.028 | 232.410 | ||||

| 40 | 0.688 | 17.475 | 171.293 | 255.148 | |||

| 0.750 | 19.050 | 186.233 | 277.401 | ||||

| 30 | 30.000 | 762 | 0.250 | 6.350 | 79.433 | 118.318 | |

| 0.281 | 7.137 | 89.189 | 132.851 | ||||

| 10 | 0.312 | 7.925 | 98.925 | 147.353 | |||

| STD | 0.375 | 9.525 | 118.648 | 176.731 | |||

| 0.438 | 11.125 | 138.286 | 205.983 | ||||

| 20 XHY | 0.500 | 12.700 | 157.530 | 234.647 | |||

| 30 | 0.625 | 15.875 | 196.078 | 292.066 | |||

| 0.688 | 17.475 | 215.380 | 320.817 | ||||

| 0.750 | 19.050 | 234.293 | 348.988 | ||||

| 3/4 | 1.050 | 27 | 40 STD | 0.113 | 2.870 | 1.131 | 1.684 |

| 80 STD | 0.154 | 3.912 | 1.474 | 2.195 | |||

| 36 | 36.000 | 914 | 0.250 | 6.350 | 95.453 | 142.180 | |

| 0.281 | 7.137 | 107.196 | 159.672 | ||||

| 10 | 0.312 | 7.925 | 118.918 | 177.133 | |||

| STD | 0.375 | 9.525 | 142.678 | 215.525 | |||

| 0.438 | 11.125 | 166.353 | 247.790 | ||||

| 20 XHY | 0.500 | 12.700 | 198.570 | 282.372 | |||

| 0.625 | 15.875 | 236.128 | 351.723 | ||||

| 0.688 | 17.475 | 259.467 | 386.487 | ||||

| 0.750 | 19.050 | 282.353 | 420.576 | ||||

| 48 | 48.000 | 1219 | STD | 0.375 | 9.525 | 190.738 | 284.112 |

| 0.438 | 11.125 | 222.487 | 331.404 | ||||

| XHY | 0.500 | 12.700 | 253.650 | 377.822 | |||

| 0.750 | 19.050 | 378.473 | 563.750 | ||||

| 0.875 | 22.225 | 440.383 | 655.969 | ||||

We provide 316 stainless rectangle tube with precise dimensions and tight tolerances to ensure seamless integration into your systems.

| Outer Diameter in Mm | Wall Thickness in Mm | Sizes Inch. | Schedule | Kg/m |

|---|---|---|---|---|

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

| Grades | Carbon | Manganese | Phosphorous | Sulphur | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| 304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

We can provide stainless steel rectangular hollow section in basically any size

| Material | Temperure | Heat | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| Min. | Treatment | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| 304 | 1900 (1040) | Solution | 30(205) | 75(515) | 35 |

| 304L | 1900 (1040) | Solution | 25(170) | 70(485) | 35 |

| 316 | 1900(1040) | Solution | 30(205) | 75(515) | 35 |

| 316L | 1900(1040) | Solution | 25(170) | 70(485) | 35 |

Application of stainless steel rectangular hollow section

- Marine applications

- Aerospace industry

- Automotive manufacturing

- Brewing equipment

- Dairy equipment

Packaging of ss rectangular tube

Different packaging techniques are employed based on the type and size of steel tubes to guarantee secure transportation. While we offer packaging guidelines for common pipe types, we stress the importance of extra precautions during sealift handling and transportation to protect against damages resulting from movement and bending.

Frequently asked questions

What are the key features of stainless steel rectangular box section?

stainless steel rectangular box section is characterized by its rectangular shape, high strength, corrosion resistance, and aesthetic appeal.

What is the typical size range of ss rectangular tube?

ss rectangular tube is available in a wide range of sizes, with varying dimensions of width, height, and wall thickness to suit different applications.

How is stainless steel rectangular hollow section commonly manufactured?

stainless steel rectangular hollow section is commonly manufactured by either welding stainless steel strips or by extrusion, followed by sizing and finishing processes.

What are the typical applications of 316 stainless steel rectangular tubing?

316 stainless steel rectangular tubing finds applications in industries such as construction, architecture, automotive, furniture, and decorative purposes, where a rectangular shape is desired for structural or aesthetic purposes