Buy 304 SS heavy duty pipe clamp in custom sizes at Best Price

316 SS clamps are widely used in high cyclic pressure applications

Table of content

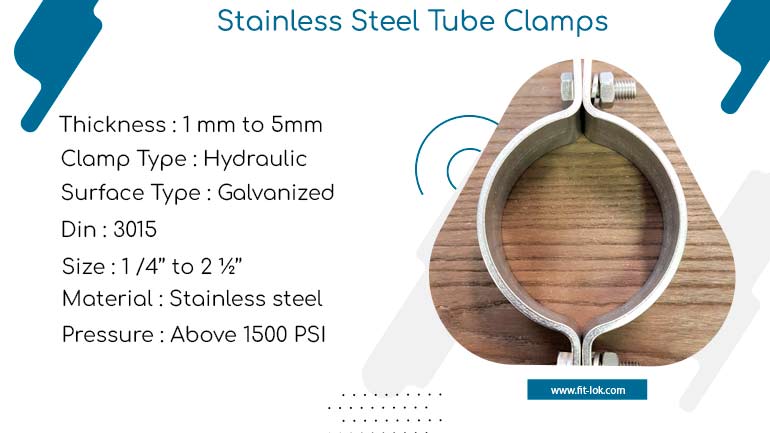

- Stainless steel tube clamps specification

- Different types of ss tube clamps

- Chemical composition of ss tube clamp

- Mechanical properties of stainless steel pipe clamps

- SS tube clamps equivalnet grade

- Advantages of ss tube clamps

- SS Tube Clamps Standard configuration

- Dimensions of SS Pipe Clamps

- Size range of Stainless steel tube clamp

- SS pipe clamp temperature range

| Locking Screw | M6 TO M24 |

| Material | Carbon steel , Stainless Steel 304 , Stainless steel 316 , As per client Request. |

| Size Range | 6 MM TO 219.1 MM |

| Pressure | For W.P 6000 PSI, 400 BAR |

| Clamp Halve | Polypropylene, Polyamide, Aluminum |

Stainless Steel Tube Clamps

304 SS heavy duty pipe clamp

316 SS clamps

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Ti | Fe | |

| 304 | min. | 18.0 | 8.0 | |||||||||

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| 304L | min. | 18.0 | 8.0 | |||||||||

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | min. | 0.04 | 18.0 | 8.0 | ||||||||

| max. | 0.10 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SS 310 | 0.015 max | 2 max | 0.015 max | 0.020 max | 0.015 max | 24.00 26.00 | 0.10 max | 19.00 21.00 | 54.7 min | |||

| SS 310S | 0.08 max | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 0.75 max | 19.00 21.00 | 53.095 min | |||

| SS 310H | 0.04 0.10 | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 19.00 21.00 | 53.885 min | ||||

| 316 | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316L | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316TI | 0.08 max | 10.00 14.00 | 2.0 max | 0.045 max | 0.030 max | 16.00 18.00 | 0.75 max | 2.00 3.00 | ||||

| 317 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 57.845 min | ||||

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 min | |||

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 5(C+N) 0.70 max | |||

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 4(C+N) 0.70 max | |||

| 347/ 347H | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 20.00 | 9.0013.00 | |||||

| 410 | min. | 11.5 | ||||||||||

| max. | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | min. | 23.0 | 0.10 | |||||||||

| max. | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| 904L | min. | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| max. | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 304/ 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 304H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 310 / 310S / 310H | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 306/ 316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 316L | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 317 | 7.9 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 321 | 8.0 g/cm3 | 1457 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 347 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 904L | 7.95 g/cm3 | 1350 °C (2460 °F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35 % |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4301 | S30409 | – | – | – | – | – |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | – | – | – | – | – |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| SS 317 | 1.4449 | S31700 | SUS 317 | – | – | – | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | – | – | – | X2CrNiMo18-15-4 |

| SS 321 | 1.4541 | S32100 | SUS 321 | – | – | – | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | – | – | – | X12CrNiTi18-9 |

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | – | – | – | X6CrNiNb18-12 |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

- Stronger fastening latches for high load capacity

- Enhanced braking resistance due to increased material cross-section area

| S | Complete Clamp for Weld Mounting [STW] |

|---|---|

| R1S | Complete Clamp for mounting to RAL-1 [RCN-1] |

| US | Complete Clamp for mounting to Strut Channel [UCN] |

| BS | Complete Clamp for Bolt Mounting [BAP] |

| DS | Complete Double Clamp for Weld Mounting [DOW] |

| SSK | Stacking Kit [SAF + STB] |

| R0S | Complete Clamp for mounting to RAL-0 [RCN-0] |

| G*S | Complete Clamp for Group Weld Plate Mounting [GRW] *is the number of positions |

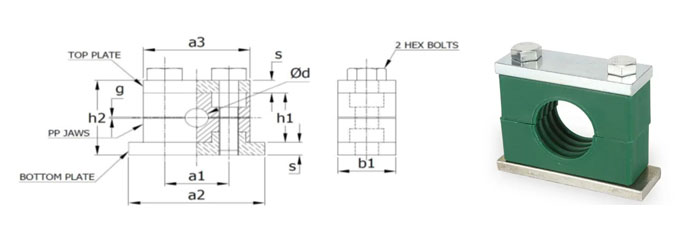

| ONE SET = ONE TOP PLATE + ONE BOTTOM PLATE + 2 HEX BOLTS + 2 PP JAWS | |||||||||||

| DIN | Sizes | PIPE OD | |||||||||

| GROUP | Dia – d | a2 | a3 | a1 | b1 | G | S | h1 | h3 | HEX BOLT SIZE | |

| IN MM | IN MM | IN MM | IN MM | IN MM | IN MM | IN MM | IN MM | IN MM | LENGTH | ||

|

GROUP 1

|

|||||||||||

| 1 | 6 MM | 6 | 72 | 55 | 33 | 30 | 0.6 – 1 | 8 | 32 | 48 – 49 | M10 X 45 MM |

| 6.4 MM | 6.4 | ||||||||||

| 8 MM | 8 | ||||||||||

| 9.5 MM | 9.5 | ||||||||||

| 10 MM | 10 | ||||||||||

| 12 MM | 12 | ||||||||||

| 12.7 MM | 12.7 | ||||||||||

| 14 MM | 14 | ||||||||||

| 15 MM | 15 | ||||||||||

| 16 MM | 16 | ||||||||||

| 17.2 MM | 17.2 | ||||||||||

| 18 MM | 18 | ||||||||||

|

GROUP 2

|

|||||||||||

| 2 | 19 MM | 19 | 86 | 70 | 45 | 30 | 0.6 – 1 | 8 | 48 | 64 | M10 X 60 MM |

| 20 MM | 20 | ||||||||||

| 21.3 MM | 21.3 | ||||||||||

| 22 MM | 22 | ||||||||||

| 25 MM | 25 | ||||||||||

| 26.9 MM | 26.9 | ||||||||||

| 28 MM | 28 | ||||||||||

|

GROUP 3

|

|||||||||||

| 3 | 30 MM | 30 | 100 | 85 | 60 | 30 | 0.6 – 1 | 8 | 60 – 62 | 76 – 78 | M10 X 70 MM |

| 32 MM | 32 | ||||||||||

| 33.7 MM | 33.7 | ||||||||||

| 35 MM | 35 | ||||||||||

| 38 MM | 38 | ||||||||||

| 40 MM | 40 | ||||||||||

| 42 MM | 42 | ||||||||||

|

GROUP 4

|

|||||||||||

| 4 | 42.3 MM | 42.3 | 140 | 115 | 90 | 50 | 2 | 10 | 89 – 92 | 109 – 112 | M12 X 100 MM |

| 48.3 MM | 48.3 | ||||||||||

| 50.8 MM | 50.8 | ||||||||||

| 54 MM | |||||||||||

| 60.3 MM | 60.3 | ||||||||||

| 65 MM | 65 | ||||||||||

|

GROUP 5

|

|||||||||||

| 5 | 70 MM | 70 | 180 | 152 | 122 | 65 | 2 | 10 | 120 – 122 | 137 – 140 | M16 X 130 MM |

| 73 MM | 73 | ||||||||||

| 76.2 MM | 76.2 | ||||||||||

| 88.9 MM | 88.9 | ||||||||||

|

GROUP 6

|

|||||||||||

| 6 | 101.6 MM | 101.6 | 230 | 210 | 168 | 80 | 3 | 16 | 163 – 168 | 193 – 195 | M20 X 180 MM |

| 114.3 MM | 114.3 | ||||||||||

|

GROUP 7

|

|||||||||||

| 7 | 141.3 MM | 141.3 | 275 | 254 | 205 | 100 | 3 | 16 | 200 | 230 – 232 | M24 X 225 MM |

| 168.3 MM | 168.3 | ||||||||||

|

GROUP 8

|

|||||||||||

| 8 | 219.1 MM | 219.1 | 345 | 323 | 265 | 130 | 3 | 25 | 250 | 320 | M30 X 300 MM |

| Clamping Range mm | Size ( inches) | Thickness( mm) | Width (w) ( mm) |

| 20-25 | 1/2″ | 2 | 20 |

| 26-30 | 3/4″ | 2 | 20 |

| 32-36 | 1″ | 2 | 20 |

| 38-44 | 1 1/4″ | 2 | 20 |

| 47-51 | 1 1/2″ | 2 | 20 |

| 60-64 | 2″ | 2 | 20 |

| 74-80 | 2 1/2″ | 2 | 20 |

| 87-92 | 3″ | 2 | 20 |

| 113-118 | 4″ | 2 | 20 |

| 138-142 | 5″ | 2 | 20 |

| 160-167 | 6″ | 2 | 20 |

| 215-220 | 8″ | 2 | 20 |

| Temperature range | -20°C to +150°C |

|---|