Leading Manufacturer of Flanged thermowell in India

Thermowell is widely used to protect the temperature sensors against working conditions that are severe. It is actually in the shape of a cylinder of varying thickness with only one end of the cylinder open. A Thermocouple, RTD or a Temperature Gauge is installed in it through the other opening of the fermenting tank. Many other functions are also served by a thermowell apart from protecting the instruments.

It becomes easy to replace the sensor when fixed in a thermowell and probabilities of getting contaminated are also reduced. Thermowells, therefore, are purposely designed in order to protect measuring instruments used under high pressure and highly demanding procession.

Check Sizes and Weight chart of Tri clamp/ Threaded Thermowell online!

Threaded thermowell is mounted on the process piping or a vessel making it easy to fit and remove it. Even though, this is the most commonly used mounting method, it has the least pressure rating because of threaded joints that are likely to leak.

Welded thermowell are employed in applications where the flow is very fast, temperature is high and also pressure is high and are not separable from the process pipes or vessels. Although it is leak proof its removal is complex and the only way to get the thermowell out is to cut it off.

Table of content

| INSERTION LENGTH | 2″ TO 32″ |

| THREAD | NPT, BSPP, BSPT, SOCKETWELD |

| SHANK | TAPERED, STEPPED, PARALLEL |

| BORE SIZE | 4 MM TO 13 MM |

| CONNECTION | THREADED, TUBE END, SOCKET WELD, FLANGE END |

| PROCESS CONNECTION | 1/2″ TO 2″ |

| CONNECTION | 1/2″ TO 2″ |

| MATERIAL | SS 316, SS 304, BRASS, SS 316 TI, CS, COPPER, DUPLEX, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L & TITANIUM, ALL OTHER ALLOYS |

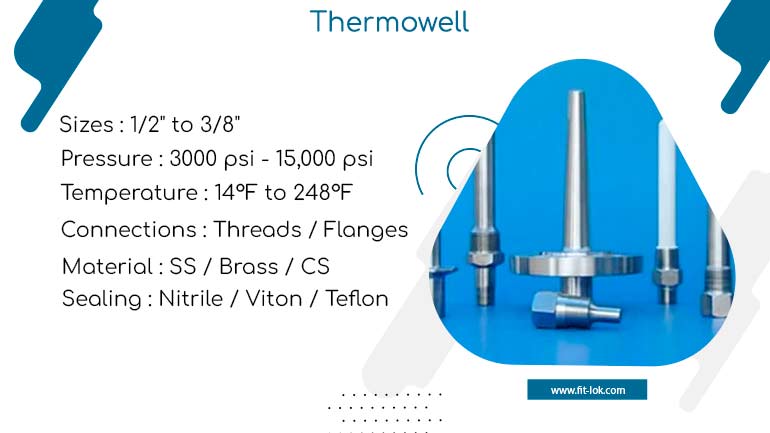

Thermowell

Flanged thermowell

Threaded Thermowell

- ASME 19.3TW

- IEC 61520:2000 Metal thermowells for thermometer sensors

- ASME B40.9 Thermowells for Thermometers and Elastic Temperature Sensors

They protect temperature sensors including thermocouple, thermometer, and thermistor from pressure, or velocity of the material, or corrosive atmosphere that is hazardous to the measuring instrument. They also contribute to the prolonging of the lifetime of the sensor, the replacement of the sensor without the need to deplete the system and the subsequent decreased possibility of contamination. High pressure thermowells are produced using the bar stock in order to maintain the integrity of the parts.

The principle behind a thermowell involves passing a temperature sensor through a hollow tube to collect heat from a process fluid.

- The process fluid transfers heat to the thermowell wall.

- The thermowell wall transfers heat to the sensor.

- The sensor responds to changes in temperature.

| Temperature range | -200 to 650 °C |

| Pressure | 50 bar (725 psi) |

- 1/2″ NPT

- G1/4″

- G1/2″

- weld-in adapter spherical

- weld-in adapter cylindrical