We keep ready stock of stainless steel pipe cap fittings

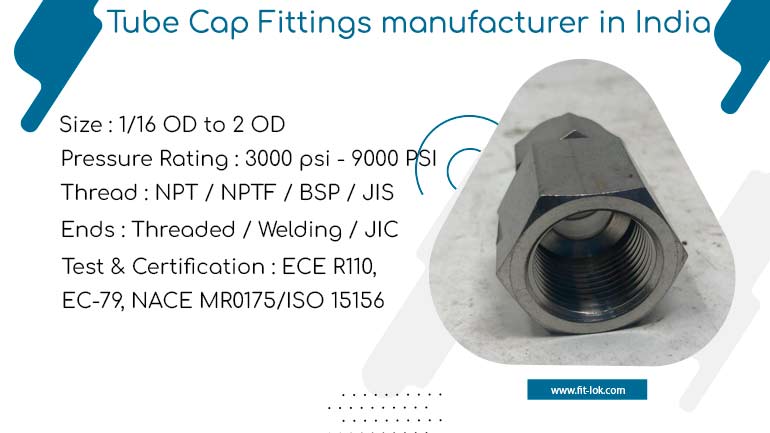

Tube cap fittings are specialised components that are used to securely seal the open ends of tubes and pipes. They are available in a variety of sizes and designs, with some having female threads on the inside to screw onto the tube’s male threads and others having a smooth inner surface to fit over the tube’s outer diameter. Tube cap fittings provide a dependable and leak-free closure, preventing fluids or gases from escaping and protecting the fluid system’s integrity.

We are manufacturer of pipe cap fittings in India

Tube cap fittings’ primary role is to seal off open ends in fluid systems. It produces a tight and secure seal by putting the cap over the open end of the tube or screwing it into the tube’s male threads. Tube cap fittings keep fluids or gases kept within the system, reducing leaks and damage. Female threads on the interior of threaded tube cap fittings allow them to be fitted onto the male threads of the tube or pipe.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

pipe cap fittings

tube light cap fittings

tube fitting end cap

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

- Aerospace industry

- Marine applications

- Water treatment

- HVAC systems

- Automotive applications

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Packaging of Tube Cap Fittings

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What are Tube Cap Fittings, and how are they used in tubing systems?

Tube Cap Fittings are protective fittings used to seal the end of a tube or pipe, preventing the ingress of contaminants and maintaining system integrity.

What are the common sizes and materials available for Tube Cap?

Tube Cap are available in various common sizes and materials such as stainless steel, brass, or plastic, providing options for different tubing sizes and compatibility with various applications.

What are the key features and benefits of using Tube Cap Fittings in various industries and applications?

The key features and benefits of using Tube Cap Fittings include secure sealing, protection against dust and debris, corrosion resistance, and ease of installation, making them suitable for industries such as plumbing, HVAC, and automotive.