Trust us as one of the finest Brass union reducing tee manufacturers in India

A union tee, also known as a tee union, is a pipe fitting used to make a branching connection in a fluid system. It has three female-threaded holes arranged in a T configuration. The central entrance connects to the main pipeline, while the other two openings allow extra pipes to be connected in other directions. Union tees are often supplied with union nuts for simple assembly and removal, allowing for quick fluid system maintenance and modifications.

Choose us as your trusted distributor for top-notch reducing union tee

A union tee’s principal function is to permit branching connections in fluid systems. The union tee allows fluid to flow in different directions from the main pipeline by uniting three pipes at right angles. Union tees are useful components in a variety of plumbing and industrial applications due to their branching capability, which optimises the circulation of liquids or gases within the fluid system.

Table of content

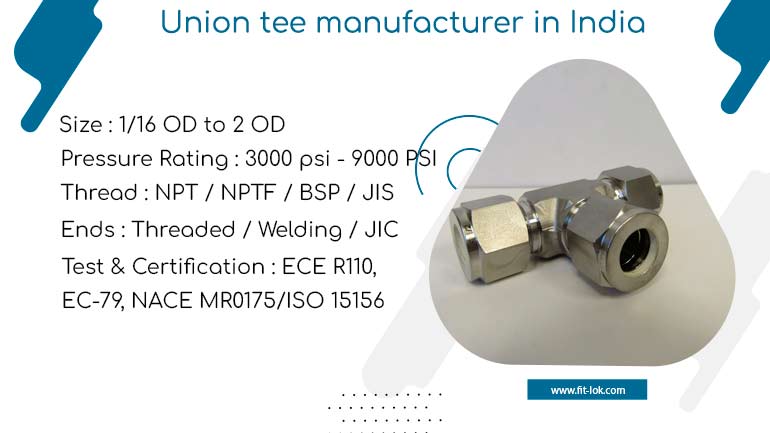

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

Union Tee

Reducing Union Tee

brass union reducing tee

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

brass union reducing tee are sourced from reliable manufacturers and available in various dimensions

- Dairy equipment

- Automotive manufacturing

- Aerospace industry

- Marine applications

- Brewing equipment

We guarantee quick turnaround times and hassle-free delivery of union brass tee products

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Take advantage of our competitive stainless steel union tee price list

Packaging of Union Tee

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What are the benefits of employing Union Tee Tube Fittings?

The ease of installation, disassembly, and reassembly of Union Tee Tube Fittings allows for piping system adjustments or repairs. At the T-junction of three tubes, they create a secure and leak-free connection.

What are the most prevalent applications for Union Tee Tube Fittings?

Union Tee Tube Fittings are commonly used in plumbing, pneumatic and hydraulic systems, and other applications that require a T-shaped junction of tubes.

How do you put a Union Tee Tube Fitting together?

To install a Union Tee Tube Fitting, insert the tubes into the relevant tube connections and tighten the union nut to secure the tubes in place. Alignment and sealing procedures such as thread sealant tape or pipe dope may be required.