Are you looking for Weld neck flange nozzle manufacturer in India

Weld nozzle flange are the most used and critical part to establish piping systems in various businesses. A flange is a round disc shaped element fastened around a hole for connecting pipes, valves, pump, and other equipments. In piping system, Flanges can be used to connect, and they come in various categories of sizes. Weld neck flange nozzle allow easy access to the vessel for repairing or rebuilding, for cleaning inside the vessel or for inspection. In pipes flanges are of very useful because they can be fitted by welding or screwed. These flanges are of various kinds based on the applications, the structure and the kind of material used.

Refer sizes and dimensions of SAE Weld Nozzle Flange

Fit-Lok is the industry leader in manufacturing and supplying of the SAE Weld Nozzle Flange . Here, you can find information about the quality of the material we are using for manufacturing of these Flanges. To make them perfectly suitable for every application, we are pin pointing to produce the most accurate and high quality Nozzle Flanges. We present the Flange range in a different material, alloys and specifications to meet their requirements. These Nozzle Flanges are made by adhering to all industrial and international standards. To ensure quality, all our experts and skilled professionals are conducting testing and checking of the whole manufacturing process. They oversee and scrutinize the Flanges’ manufacturing procedure from the choice of the material to the point of labeling.

Currently, we doing everything possible to ensure that we meet the quality and demand required of us by clients. Since we have clients from many places, and thus we are providing the comfort of doorstep delivery. In addition to reasonable rates and highest quality, we also offering perfectly matching nozzle flange for all industrial usages. In order to improve on the current demands of Nozzle Flanges and other products, we have upgraded our manufacturing technique and equipment. This has a special effect of helping us to manufacture the most accurate Nozzle Flanges with a fine finish.

Table of content

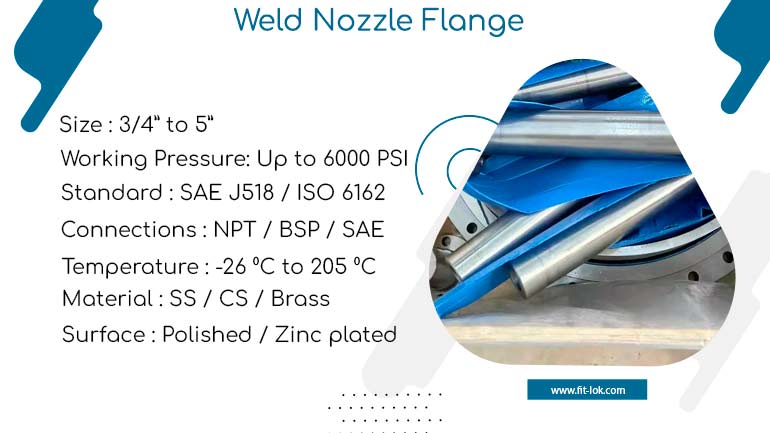

| Type | Weld nozzle flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

Weld nozzle flange

Weld neck flange nozzle

SAE Weld Nozzle Flange

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Easy Installation

- Interchangeability

- Sealing Options

- Temperature Resistance

- Corrosion Resistance

- Aluminium Die-Casting Machinery

- Sintering Machinery

- Hydraulic Presses

- Industrial Hydraulics

- Injection Moulding Machinery

- Steel Mills